Unveiling Design Optimisation for Mechanical and Automotive Parts

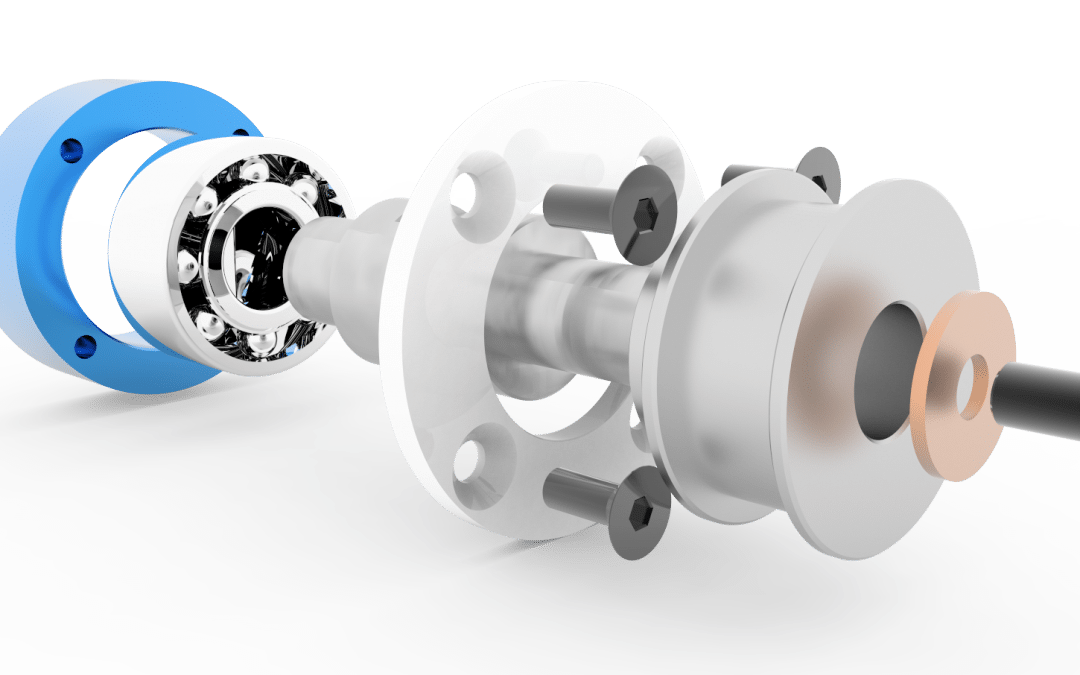

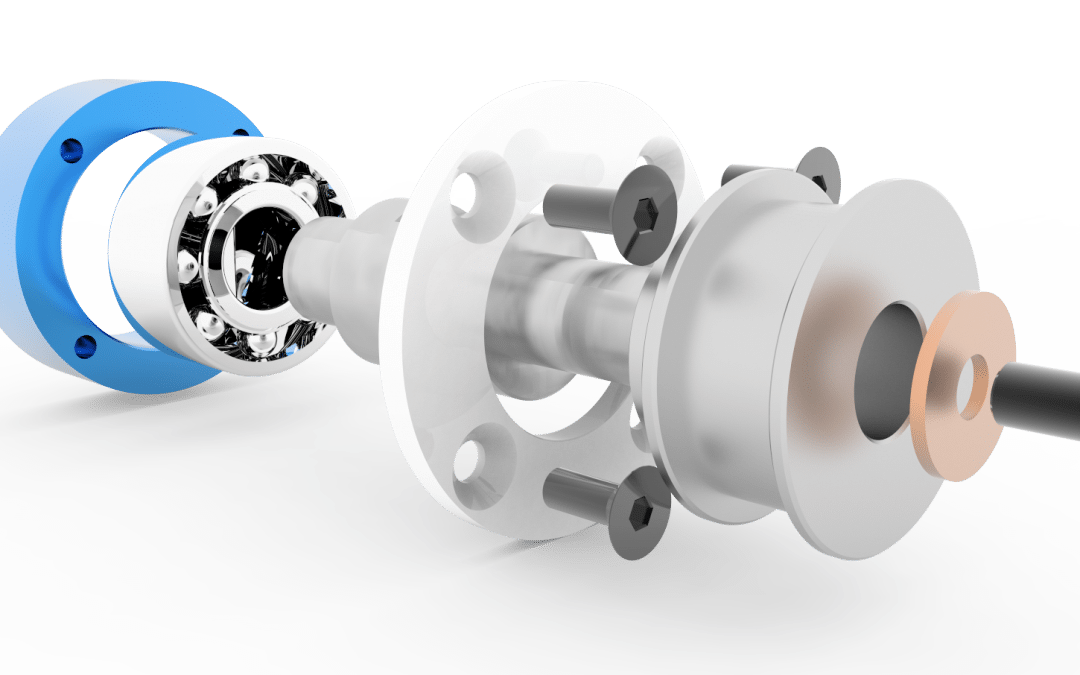

Definition: Design optimisation for mechanical and automotive parts in reverse engineering involves systematically improving the digital representation of components, ensuring they meet or exceed performance standards. This process focuses on refining key parameters, such as structural integrity, material selection, and manufacturability, to elevate the overall functionality of mechanical and automotive parts.

Key Aspects of Optimisation:

Material Selection and Properties: Optimising material choices based on performance requirements, durability, and weight considerations.

Structural Integrity: Strengthening component structures to withstand operational loads and environmental conditions.

Performance Enhancement: Fine-tuning designs to improve factors such as aerodynamics, thermal management, and overall efficiency.

Manufacturability: Ensuring that optimized designs are feasible for mass production, considering manufacturing processes and constraints.

Benefits of Design Optimisation for Mechanical and Automotive Parts:

1. Enhanced Performance: Optimization enables the enhancement of critical performance metrics, such as mechanical strength, thermal efficiency, and operational reliability, contributing to overall component excellence.

2. Lightweighting for Efficiency: By optimizing material usage and structural designs, weight reduction can be achieved without compromising performance, leading to increased fuel efficiency in automotive applications and improved overall efficiency in mechanical components.

3. Cost-Efficiency: Design optimization identifies cost-effective solutions by streamlining material usage, manufacturing processes, and minimizing unnecessary complexities. This ensures that the final product meets performance standards within budget constraints.

4. Durability and Reliability: Structural enhancements and material optimization contribute to increased durability and reliability, extending the lifespan of mechanical and automotive components under varying operational conditions.

Applications of Design Optimisation in Reverse Engineering for Mechanical and Automotive Parts:

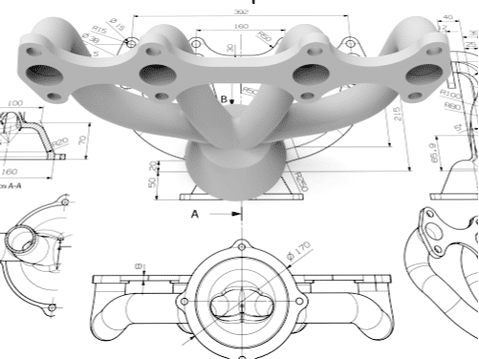

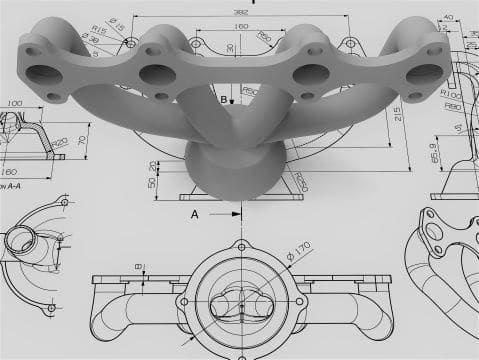

1. Engine Components Optimization: Reverse engineering allows for the optimization of engine components, improving combustion efficiency, reducing weight, and enhancing overall performance.

2. Suspension System Enhancements: Optimizing suspension components through reverse engineering can lead to improvements in ride comfort, handling, and overall vehicle stability.

3. Structural Reinforcement in Machinery: Mechanical parts in industrial machinery can be optimized for increased structural integrity, reducing wear and tear and improving the reliability of the entire system.

4. Exhaust System Performance: Reverse engineering enables the optimization of exhaust systems, addressing factors such as emissions, noise reduction, and thermal efficiency in automotive applications.

Benefits of Design Optimisation for Mechanical and Automotive Parts:

1. Enhanced Performance: Optimization enables the enhancement of critical performance metrics, such as mechanical strength, thermal efficiency, and operational reliability, contributing to overall component excellence.

2. Lightweighting for Efficiency: By optimizing material usage and structural designs, weight reduction can be achieved without compromising performance, leading to increased fuel efficiency in automotive applications and improved overall efficiency in mechanical components.

3. Cost-Efficiency: Design optimization identifies cost-effective solutions by streamlining material usage, manufacturing processes, and minimizing unnecessary complexities. This ensures that the final product meets performance standards within budget constraints.

4. Durability and Reliability: Structural enhancements and material optimization contribute to increased durability and reliability, extending the lifespan of mechanical and automotive components under varying operational conditions.

Applications of Design Optimization in Reverse Engineering for Mechanical and Automotive Parts:

1. Engine Components Optimization: Reverse engineering allows for the optimization of engine components, improving combustion efficiency, reducing weight, and enhancing overall performance.

2. Suspension System Enhancements: Optimizing suspension components through reverse engineering can lead to improvements in ride comfort, handling, and overall vehicle stability.

3. Structural Reinforcement in Machinery: Mechanical parts in industrial machinery can be optimized for increased structural integrity, reducing wear and tear and improving the reliability of the entire system.

4. Exhaust System Performance: Reverse engineering enables the optimization of exhaust systems, addressing factors such as emissions, noise reduction, and thermal efficiency in automotive applications.

Have you got parts or designs that need enhancing?

Design optimisation in reverse engineering for mechanical and automotive parts is a dynamic process that empowers engineers to push the boundaries of performance and efficiency.

By leveraging advanced tools and methodologies, optimization not only enhances individual components but also contributes to the overall success of mechanical systems and automotive vehicles.

As industries continue to evolve, design optimization remains a key driver of innovation, ensuring that reverse-engineered parts meet and exceed the demanding standards of the mechanical and automotive sectors.

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk