Steel Detailing Services

Fabrication Drawings for architectural & structural steelWhat is Steel Detailing?

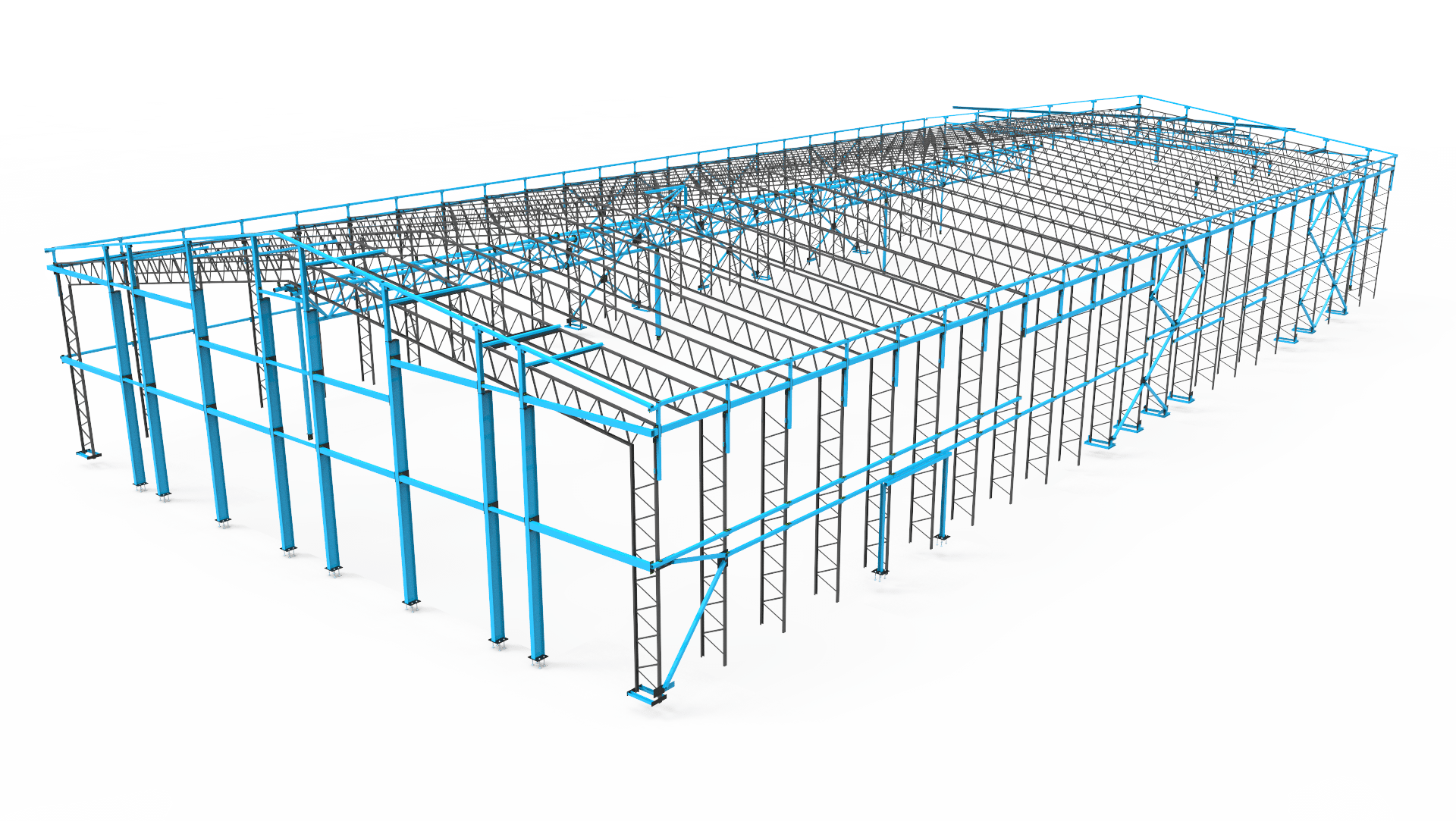

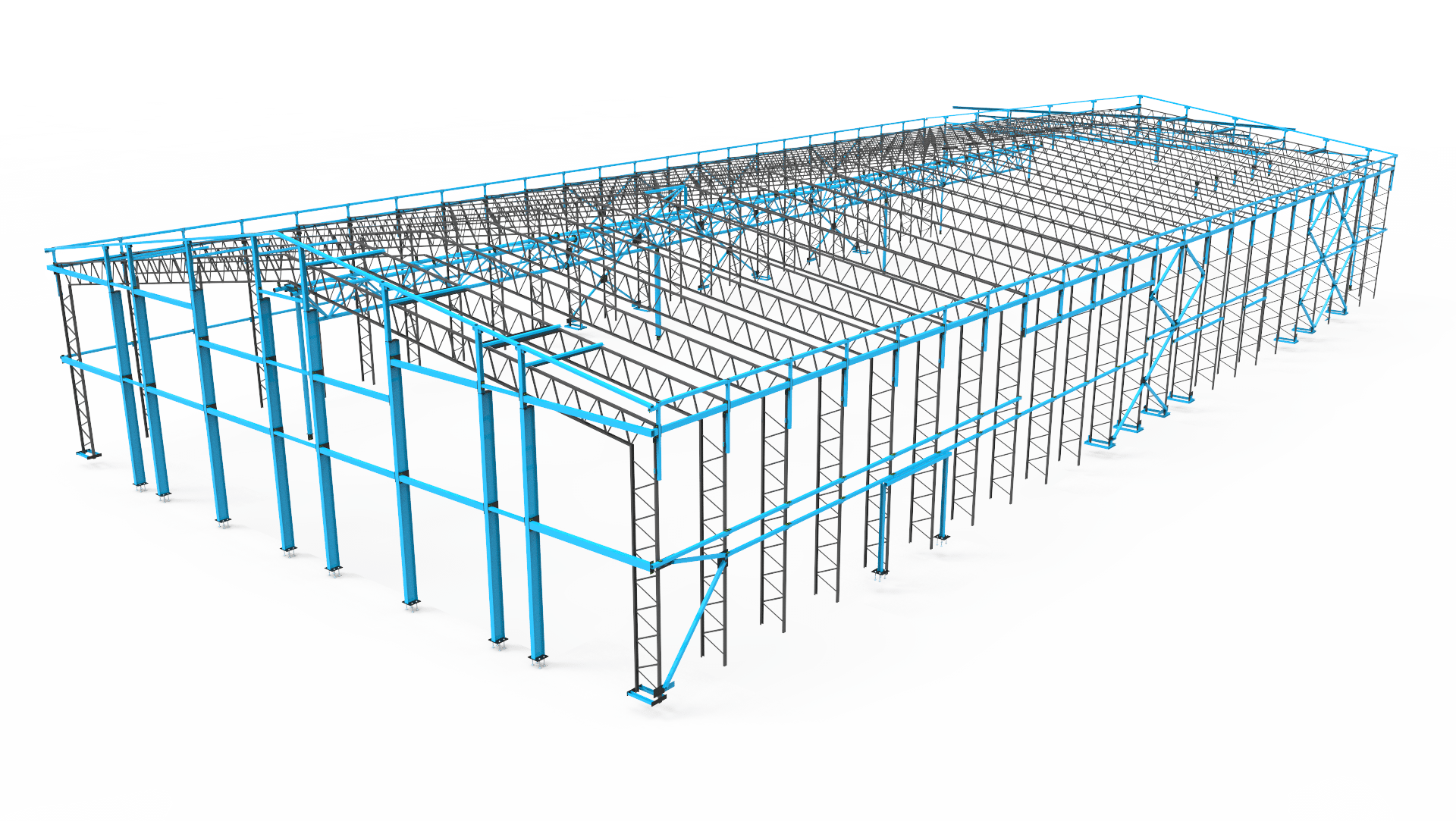

Steel detailing is the drafting process used to assist the fabrication of hot & cold rolled steel. A steel detailer uses the structural engineers’ drawings, architects drawings to produce a 3D CAD Model using specialist steel drafting software such as Tekla & Advance Steel. From the 3D CAD model, the CAD Technician will produce a set of clear, unmistakable and accurate drawings for the purpose of steelwork fabrication.

How do we detail steel?

At Restoric Design we use Autodesk Advance Steel as our preferred steel detailing CAD software package for the fabrication industry. Our steel detailers work closely with fabricators, architects, structural engineers and installers to guaranty a successful project.

We will set out the steelwork 3D CAD Models as to the architects’ drawings and size the sections as the structural engineer’s drawings. Based on the 3D Steel Model we will produce a General Assembly Drawing for approval. Once approval has been gained by the relevant parties a full set of Fabrication Drawings is produced

What is Steel Detailing?

Steel detailing is the drafting process used to assist the fabrication of hot & cold rolled steel. A steel detailer uses the structural engineers’ drawings, architects drawings to produce a 3D CAD Model using specialist steel drafting software such as Tekla & Advance Steel. From the 3D CAD model, the CAD Technician will produce a set of clear, unmistakable and accurate drawings for the purpose of steelwork fabrication.

How do we detail steel?

At Restoric Design we use Autodesk Advance Steel as our preferred steel detailing CAD software package for the fabrication industry. Our steel detailers work closely with fabricators, architects, structural engineers and installers to guaranty a successful project.

We will set out the steelwork 3D CAD Models as to the architects’ drawings and size the sections as the structural engineer’s drawings. Based on the 3D Steel Model we will produce a General Assembly Drawing for approval. Once approval has been gained by the relevant parties a full set of Fabrication Drawings is produced

Excellence in the production of Fabrication Drawings

Steel detailing service for fabricators, structural engineers and main contractors Get in touch todayStructural Steel Drawings

Structural steel drafting is a process of steel detailing specifically for structural steel.

Structural steel differs from architectural steel by the use of beams, columns, trusses, and bracing for steel frames, floors, bridges and gantries.

Structural steel drafters create drawings that depict various structural elements such as beams, columns, trusses, braces, connections, and frames. These drawings include detailed dimensions, geometries, and specifications for each component.

Initially, a 3D Model is produced using Advance Steel based on the structural engineers’ and architects’ drawings. Based on the 3D Model a set of GA drawings is produced which includes all relevant plan, elevation and section views as well as all steel-to-steel/steel-to-concrete connections.

Architectural Steel Drawings

Architectural steel refers to steel components and structures used in architectural applications, primarily for aesthetic and functional purposes in building design. Unlike structural steel, which is primarily used for the structural framework of a building or structure, architectural steel focuses on elements that contribute to the visual appeal, style, and design features of a building. Here are some common examples of architectural steel.

Architectural steel detailing includes producing fabrication drawings for steel canopies, staircases and balustrades.

The process is similar to that of structural steel. A 3D Model is produces in Advance Steel and based on this a GA drawings is created for approval.

Once approval of the General Arrangement drawings has been gained the fabrication pack is produces which includes Assembly and single-part drawings as well as part/bolt lists. Further NC and DXF files are included to aid the cutting and drilling of sections and plates.

Structural Steel Drawings

Structural steel drafting is a process of steel detailing specifically for structural steel.

Structural steel differs from architectural steel by the use of beams, columns, trusses, and bracing for steel frames, floors, bridges and gantries.

Structural steel drafters create drawings that depict various structural elements such as beams, columns, trusses, braces, connections, and frames. These drawings include detailed dimensions, geometries, and specifications for each component.

Initially, a 3D Model is produced using Advance Steel based on the structural engineers’ and architects’ drawings. Based on the 3D Model a set of GA drawings is produced which includes all relevant plan, elevation and section views as well as all steel-to-steel/steel-to-concrete connections.

Architectural Steel Drawings

Architectural steel refers to steel components and structures used in architectural applications, primarily for aesthetic and functional purposes in building design. Unlike structural steel, which is primarily used for the structural framework of a building or structure, architectural steel focuses on elements that contribute to the visual appeal, style, and design features of a building. Here are some common examples of architectural steel.

Architectural steel detailing includes producing fabrication drawings for steel canopies, staircases and balustrades.

The process is similar to that of structural steel. A 3D Model is produces in Advance Steel and based on this a GA drawings is created for approval.

Once approval of the General Arrangement drawings has been gained the fabrication pack is produces which includes Assembly and single-part drawings as well as part/bolt lists. Further NC and DXF files are included to aid the cutting and drilling of sections and plates.

Latest related CAD News

What is historic building information modelling?

Meta Description: Learn about the basics of historic building information modelling and how this technology can help with restoration projects. The preservation of historic buildings and structures is a complex and challenging endeavour. To ensure the long-term...

How to check fabrication drawings

Fabrication drawings are essential in the fabrication industry as they guide all structural construction processes. Accuracy in the drawings is therefore paramount. This article shows you how to check fabrication drawings to ensure they serve their intended purpose...

Who uses computer aided design?

Computer-Aided Design (CAD) is utilised across the design, manufacturing and construction industries, and is an invaluable tool when creating detailed visualisations. In this article, we'll outline what CAD is, who uses it and how Restoric Design can help your...

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk