What is Paper to CAD conversion in Reverse Engineering?

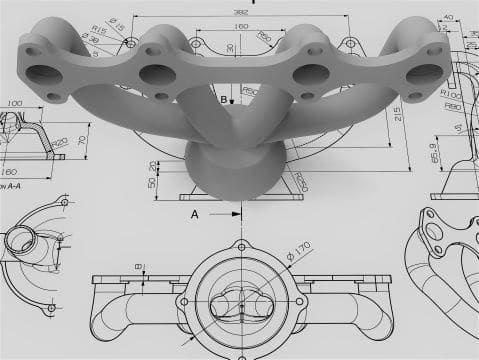

Part to CAD conversion is the methodical process of transforming physical parts or objects into digital CAD models. This conversion enables engineers to recreate, analyse, and modify existing components in a digital environment, seamlessly integrating them with modern design and manufacturing processes.

Key Components of the process:

- Data Acquisition: Gathering precise measurements and data from the physical part using various technologies such as hand measuring wiht calipers or the use of our Faro Arm a coordinate measuring machine (CMM).

- Conversion Software: Utilising advanced CAD software such as Solidworks or Inventor to translate the acquired data into a detailed and accurate digital representation of the physical part.

Benefits of Part to CAD Conversion in Reverse Engineering:

1. Precision and Accuracy: Digital CAD models derived from Part to CAD conversion offer unparalleled precision, capturing intricate details and dimensions with high accuracy. This ensures that the digital representation faithfully mirrors the physical part.

2. Time Efficiency: The conversion process significantly reduces the time required for reverse engineering projects. Digital CAD models allow engineers to swiftly analyze, modify, and iterate on the design, expediting the overall development timeline.

3. Iterative Design Exploration: Engineers can explore multiple design iterations easily in the digital realm. This iterative process fosters creativity, enabling continuous improvement and optimization of the reverse-engineered part.

4. Compatibility with Modern Design Tools: Digital CAD models seamlessly integrate with modern design and simulation tools, facilitating a smoother transition from reverse engineering to prototyping and manufacturing.

Applications of Part to CAD Conversion in Reverse Engineering:

1. Legacy Part Recreation: Part to CAD conversion is instrumental in recreating components for which physical documentation may be outdated or nonexistent, breathing new life into legacy systems.

2. Design Modification and Optimization: Engineers can leverage digital CAD models to make precise modifications and optimizations to existing parts, enhancing performance, durability, or other critical attributes.

3. Prototyping and Manufacturing: The digital CAD models obtained through Part to CAD conversion serve as the foundation for creating prototypes and guiding the manufacturing process. This ensures that the reverse-engineered part seamlessly aligns with production requirements.

Benefits of Part to CAD Conversion in Reverse Engineering:

1. Precision and Accuracy: Digital CAD models derived from Part to CAD conversion offer unparalleled precision, capturing intricate details and dimensions with high accuracy. This ensures that the digital representation faithfully mirrors the physical part.

2. Time Efficiency: The conversion process significantly reduces the time required for reverse engineering projects. Digital CAD models allow engineers to swiftly analyze, modify, and iterate on the design, expediting the overall development timeline.

3. Iterative Design Exploration: Engineers can explore multiple design iterations easily in the digital realm. This iterative process fosters creativity, enabling continuous improvement and optimization of the reverse-engineered part.

4. Compatibility with Modern Design Tools: Digital CAD models seamlessly integrate with modern design and simulation tools, facilitating a smoother transition from reverse engineering to prototyping and manufacturing.

Applications of Part to CAD Conversion in Reverse Engineering:

1. Legacy Part Recreation: Part to CAD conversion is instrumental in recreating components for which physical documentation may be outdated or nonexistent, breathing new life into legacy systems.

2. Design Modification and Optimization: Engineers can leverage digital CAD models to make precise modifications and optimizations to existing parts, enhancing performance, durability, or other critical attributes.

3. Prototyping and Manufacturing: The digital CAD models obtained through Part to CAD conversion serve as the foundation for creating prototypes and guiding the manufacturing process. This ensures that the reverse-engineered part seamlessly aligns with production requirements.

Have you got drawings that need converting

Part to CAD conversion stands at the forefront of innovation in reverse engineering, empowering engineers to transition seamlessly from physical components to digital design. Its role in ensuring precision, time efficiency, and compatibility with modern tools is invaluable in the dynamic landscape of product development.

As industries continue to embrace digital transformation, Part to CAD conversion emerges as a key enabler for unlocking new possibilities and pushing the boundaries of what can be achieved in the realm of reverse engineering.

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk