What is Paper to CAD conversion in Reverse Engineering?

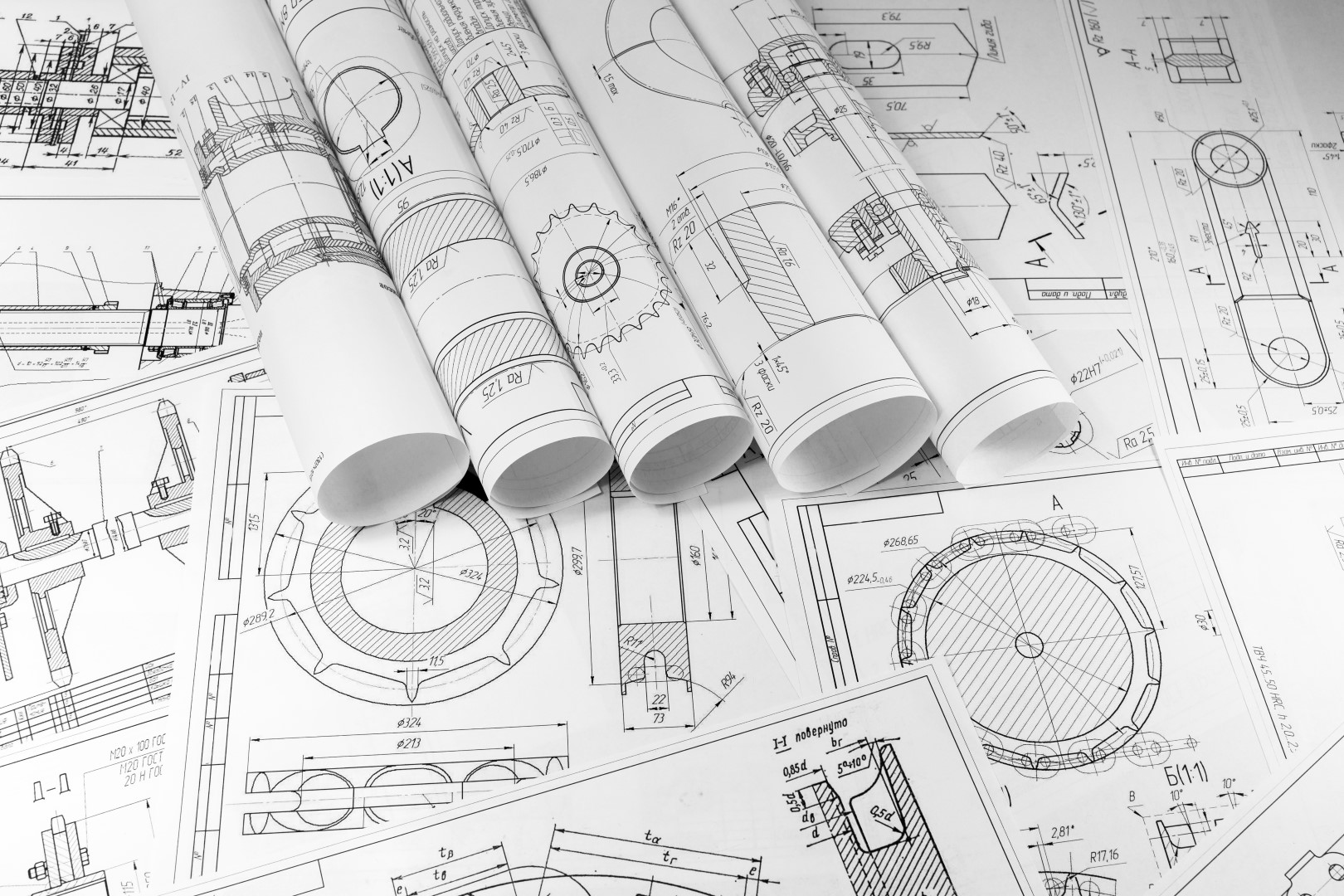

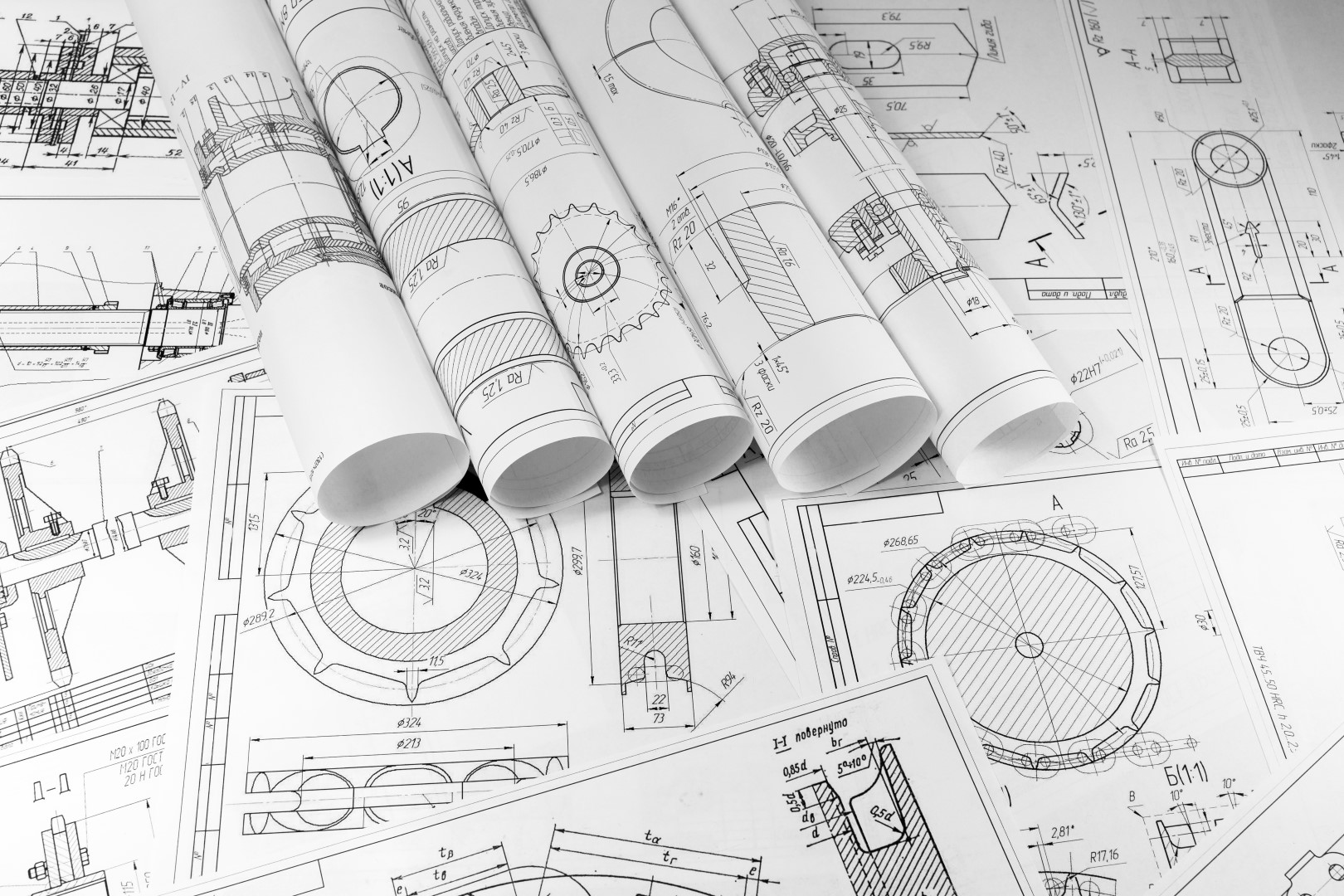

Paper to CAD conversion is the methodical process of converting hand-drawn sketches, blueprints, or paper-based designs into digital Computer-Aided Design (CAD) files. This transformation facilitates seamless integration with modern design and manufacturing processes.

Importance in Reverse Engineering:

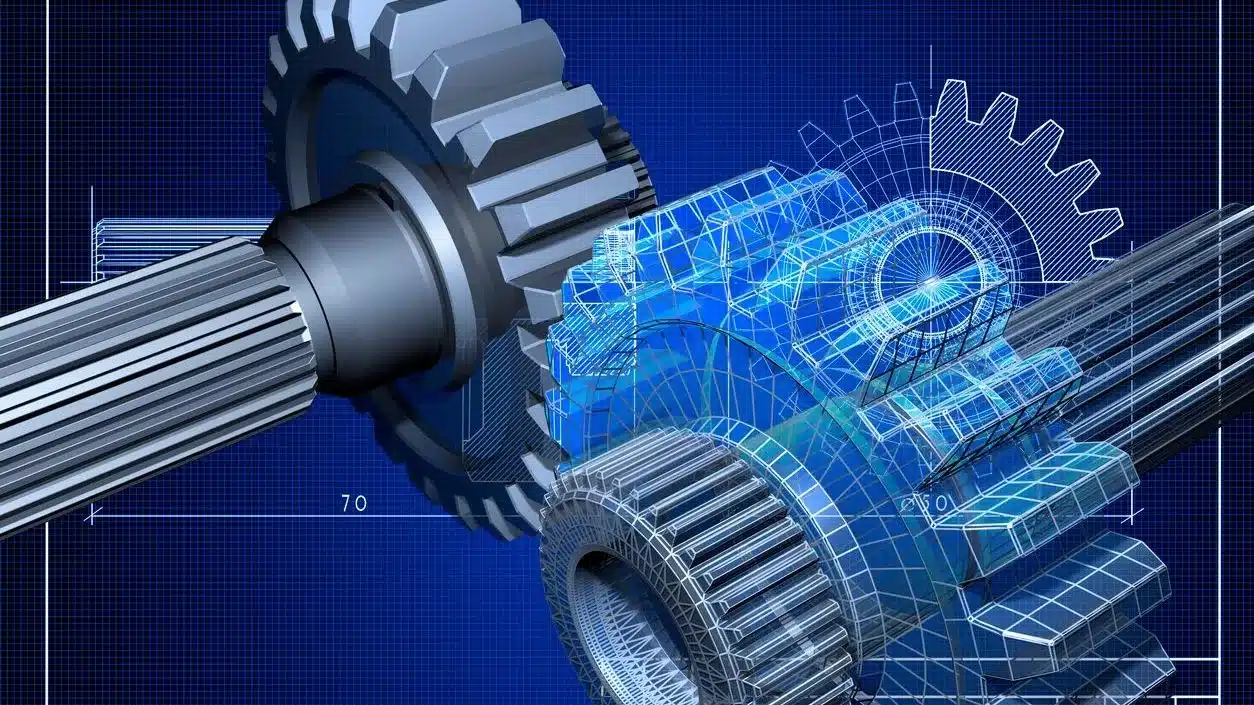

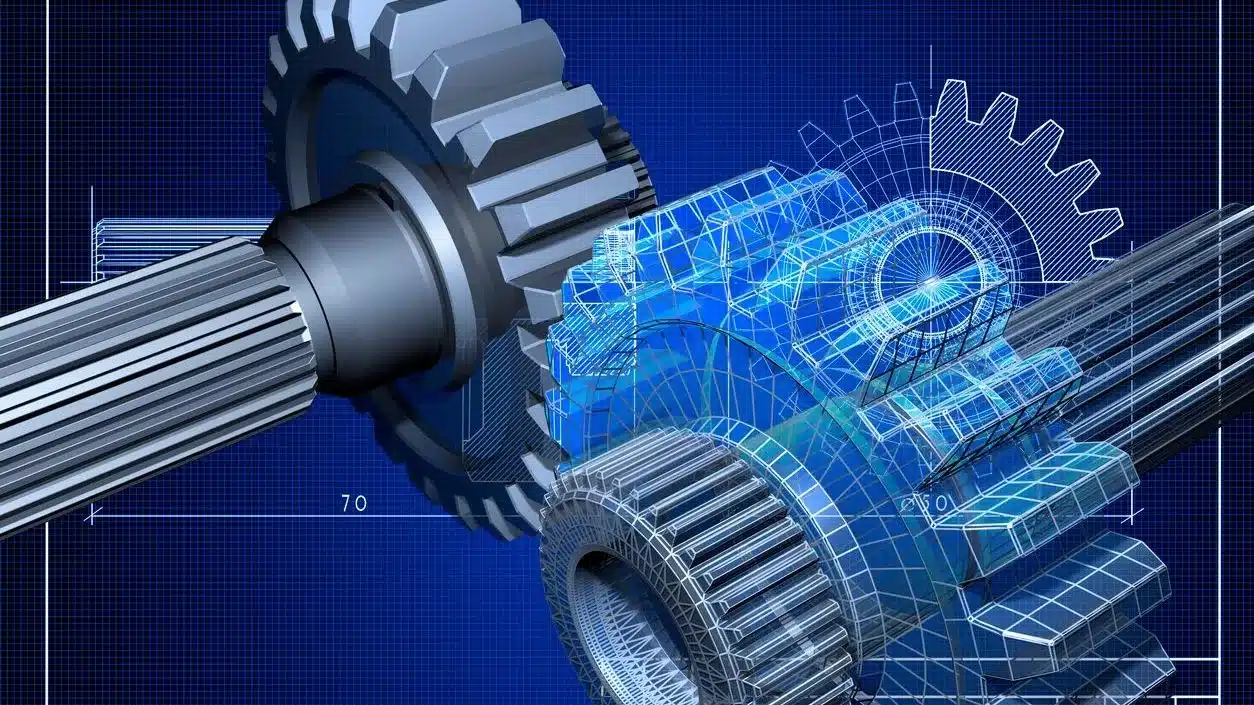

Reverse engineering involves dissecting and understanding an existing product to recreate its design. Paper to CAD conversion becomes a crucial step in this process, allowing engineers to leverage digital tools for precise analysis, modifications, and enhancements.

Key Benefits of Paper to CAD Conversion in Reverse Engineering:

1. Accuracy and Precision: Digital CAD files offer unparalleled accuracy, eliminating the discrepancies that may arise from manual measurements. This ensures that the reverse-engineered model faithfully replicates the original design.

2. Time Efficiency: Paper to CAD conversion significantly reduces the time required for reverse engineering projects. Digital files enable quick modifications and iterations, expediting the overall design process.

3. Enhanced Collaboration: Digital CAD files can be easily shared and collaborated upon by teams regardless of geographical locations. This fosters seamless communication and collaboration among engineers and stakeholders involved in the reverse engineering project.

4. Iterative Design Improvement: Digital files enable engineers to experiment with various design iterations effortlessly. This iterative process facilitates continuous improvement and optimization of the reverse-engineered model.

Applications of Paper to CAD Conversion in Reverse Engineering:

1. Legacy Component Recreation: Reverse engineering often involves recreating legacy components for which digital documentation may be lacking. Paper to CAD conversion allows for the accurate recreation of these components in a digital format.

2. Design Modification and Optimisation: Engineers can easily modify and optimize existing designs using digital CAD files. This is especially valuable when updating or improving the performance of a product.

3. Prototyping and Manufacturing: The digital files obtained through Paper to CAD conversion serve as the foundation for creating prototypes and facilitating the manufacturing process. This ensures that the reverse-engineered product aligns seamlessly with production requirements

Key Benefits of Paper to CAD Conversion in Reverse Engineering:

1. Accuracy and Precision: Digital CAD files offer unparalleled accuracy, eliminating the discrepancies that may arise from manual measurements. This ensures that the reverse-engineered model faithfully replicates the original design.

2. Time Efficiency: Paper to CAD conversion significantly reduces the time required for reverse engineering projects. Digital files enable quick modifications and iterations, expediting the overall design process.

3. Enhanced Collaboration: Digital CAD files can be easily shared and collaborated upon by teams regardless of geographical locations. This fosters seamless communication and collaboration among engineers and stakeholders involved in the reverse engineering project.

4. Iterative Design Improvement: Digital files enable engineers to experiment with various design iterations effortlessly. This iterative process facilitates continuous improvement and optimization of the reverse-engineered model.

Applications of Paper to CAD Conversion in Reverse Engineering:

1. Legacy Component Recreation: Reverse engineering often involves recreating legacy components for which digital documentation may be lacking. Paper to CAD conversion allows for the accurate recreation of these components in a digital format.

2. Design Modification and Optimisation: Engineers can easily modify and optimize existing designs using digital CAD files. This is especially valuable when updating or improving the performance of a product.

3. Prototyping and Manufacturing: The digital files obtained through Paper to CAD conversion serve as the foundation for creating prototypes and facilitating the manufacturing process. This ensures that the reverse-engineered product aligns seamlessly with production requirements

Have you got drawings that need converting

Paper to CAD conversion stands as a cornerstone in the realm of reverse engineering, propelling traditional designs into the digital age. Its role in enhancing accuracy, time efficiency, and collaborative efforts cannot be overstated.

By embracing this transformative process, engineers unlock a world of possibilities for recreating, modifying, and optimizing existing designs. As technology continues to evolve, Paper to CAD conversion remains a vital tool for seamlessly integrating the old with the new in the dynamic landscape of reverse engineering.

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk

About Us

At Restoric®, we specialise in CAD Services, Reverse Engineering, and Steel Detailing, catering to diverse industrial needs. Using AutoCAD, Advance Steel and Solidworks we bring precision and efficiency to every project. Trust Restoric® for reliable solutions and seamless execution in the realm of engineering services.

Address

Restoric® Design Ltd.

7 Paynes Park

Hitchin

Hertfordshire SG5 1EH

Tel: 01462 514 300

Email:

info@restoric.co.uk