Mechanical Material Properties

This article explains the main mechanical material properties used in mechanical engineering and mechanical design.

The understanding of these properties is essential for the material selection process in a CAD design project.

Tensile Strength

This is the ability of a material to withstand tensile (stretching) loads without rupture occurring. The material is in tension.

Compressive strength

This is the ability of a material to withstand compressive (squeezing) loads without being crushed or broken. The materials is in compression.

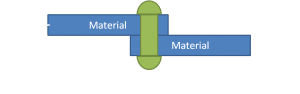

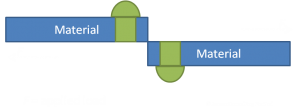

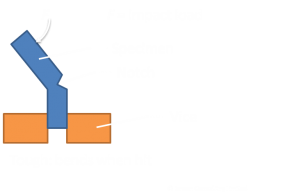

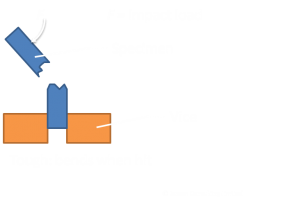

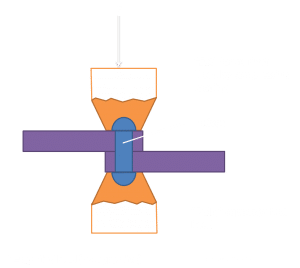

Shear Strength

This is the ability of a material to withstand offset or transverse loads without rupture occurring. The rivet connecting the two bars shown is in shear whilst the bars themselves are in tension. Note that the rivet would still be in shear if the bars were in compression.

Toughness: impact resistance

This is the ability of a material to resist shatter. If a material shatters it is brittle (e.g. glass). If it fails to shatter when subject to an impact load it is tough (e.g. rubber). Toughness should not be confused with strength. Any material in which the spread of surface cracks does not occur or only occurs to a limited extent is said to be tough.

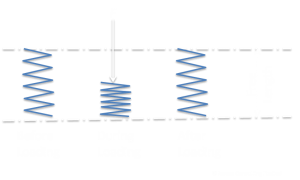

Elasticity

This is the ability of a material to deform under load and return to its original size and shape when the load is removed. Such a material would be required to make the spring as shown.

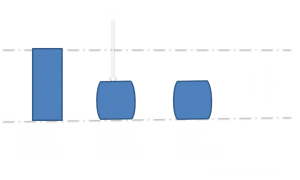

Plasticity

This property is the exact opposite of elasticity. It is the state of a material which has been loaded beyond its elastic state. Under a load beyond that required to cause elastic deformation (the elastic limit) a material possessing the property of plasticity deforms permanently. It takes a permanent set and will not recover when the load is removed.

Ductility

This is the term used when plastic deformation occurs as the result of applying a tensile load. A ductile material combines the properties of a plasticity and tenacity (tensile strength) so that it can be stretched or drawn to shape and will retain that shape when the deforming force is removed. For example, in wire drawing the wire is reduced in diameter by drawing it through a die.

Malleability

This is a term used when plastic deformation occurs as the result of applying a compressive load. A malleable material combines the properties of plasticity and compressibility, so that it can be squeezed to shape by such processes as forging, rolling and rivet heading.

Hardness

This is the ability of a material to withstand scratching (abrasion) or indentation by another hadrd body. It is an indication of the wear resistance of a material.

Processes which increase the hardness of materials also increase their tensile strength. At the same time the toughness of the material is reduced as it becomes more brittle.

Hardenability must not be confused with hardness. Hardenability is the ability of a metal to respond to the heat treatment process of quench hardening. To harden it, the hot metal must be chilled at a rate in excess of its critical cooling rate. Since any material that cools more quickly at the surface than tat the centre there is a limit to the size of bar which can cool quickly enough at its centre to achieve uniform hardness throughout. This is the ruling section for the material. The greater its hardenability the greater will be its ruling section.

Reference: Mechanical Engineers Pocket Book, Roger Timings