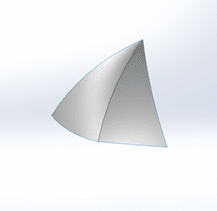

A designer or CAD modeller will sooner or later come across the need for a ‘smooth’ surface – one that has no hard edges to achieve an organic and natural look. This is more the case when designing products for commercial application. SolidWorks has a powerful tool to create smooth surfaces known as the ‘filled surface’ command. Figure 1 shows the limitations of the boundary surface command – it fails to produce a smooth surface when the profile flexes in more than two directions.

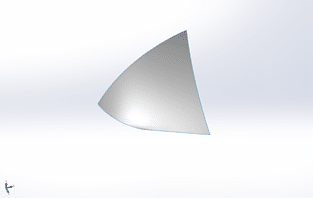

The filled surface command works in a different way. To generate a smooth surface it uses the bounding area of a sketch or adjacent surfaces. It also allows you to instruct how each ‘bounding side’ should be treated. Figure 2 shows what can be achieved using this command.

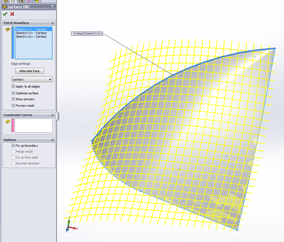

There are three boundary ‘conditions’ you can set – contact, tangency and curvature. If you are using a 2D or 3D sketch, you can only select a contact condition since no surface or other faces are present for reference. If you have a surrounding set of surfaces, you can manipulate the filled surface result by select them and applying boundary conditions.

I hope you have learnt something powerful from this tutorial. Restoric Design has designers that are competent in the use of SolidWorks and other CAD software.