Reverse Engineering is a term used to describe the process of re-constructing an existing product accurately, for the purpose of manufacturing more of the same kind or modifying it to improve upon its design. Further, there may also be a need to ‘digitize’ an original hand-crafted product that was a result of nothing more than an idea.

Reverse Engineering – from part to CAD drawing

Reverse engineering service companies are often equipped with measurement and scanning devices to derive the physical data of the product. A 3D virtual representation is often the result of these activities and it can be assumed that the accuracy of the result is dependent on the measurement technique and / or human capability.

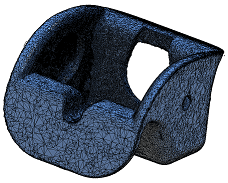

Scanning devices have made it possible to capture geometrical data that would otherwise be difficult or impossible such as a curved surface with an inconsistent radius. This is also a non-contact, non-destructive method of reverse engineering. Scanning technology has and continues to do drop in price and this makes it a feasible option for the engineer. Traditional workshop measurement tools lend themselves to human error and readings are subjective in nature. As well as this, physical contact measurement techniques mean the part to be measured is at risk of being damaged.

Possibilities and advantages

A geometrically-accurate 3D virtual model can be obtained through reverse engineering measurements. Scanning techniques will often provide ‘point cloud data’ or points in space representing the surfaces of the product. A 3D CAD model would then be created using this digital point data as a reference.

There are numerous benefits to having a 3D CAD model of the existing product. Some are:

- The ability to design a new part to fit in or around the existing product

- Carry out simulated tests to analyze the existing product and improve it

- To create a professional library of digital drawings and remove the need for paper equivalents

- To allow you to create rapid prototype parts, evaluating design additions or improvements quickly

- To monitor the performance of the existing product over time in life

Save time and money

3D scanning reduces the time taken to reverse engineer a complex product. Time is saved when considering how convenient the automated scanning process is as well as improving the efficiency of 3D model generation. Many reverse engineering companies charge hourly or day rates and both types can be reduced with the technology in place.

3D models can be ‘printed’ using dedicated 3D printers and the technology is becoming cheaper by the day. It has the obvious benefit of saving you time and money by testing and improving designs quickly and earlier in the design cycle, ensuring any issues are resolved before committing to mass production.

Reverse engineering offers many possibilities and benefits and has proved to save time and money when used as part of the product development process. Restoric Design offers reverse engineering services and has 3D scanning and measuring facilities available.

Restoric Design is a UK based company operating in Hitchin and Cambridge, they provide Engineering Design Services in Mechanical Design and Product Design. If you would like to find out more about the company and the services they offer please visit their website at www.jensen-consulting.co.uk also keep up to date with them via Twitter @InfoRestoric

References:

http://www.3dscanco.com/services/reverse-engineering.cfm#parametric_model