New Technical Drawings for Old car parts

The challenge of maintaining old cars

One of the biggest challenges in the old car movement is spare parts or technical drawings of them.. Some car companies have now got a heritage division such as Mercedes. Which is great for 60’s & 70’s cars. The problem is that these heritage division only really cover cars where there is still a reasonably good used parts market.

What if you have something older – pre-war – maybe even pre-war WW1?

It will be close to impossible to get a part from your local dealer for two reasons:

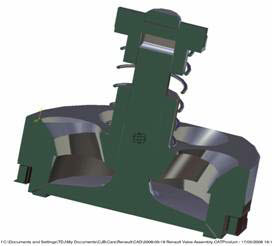

They will have no idea what you are talking about. I believe your local Renault dealer will be slightly tested if you request a new valve assembly for your 1903 Renault.

The manufacturer you would like the part from does not existing any more. There where hundreds of pre-war car companies compared to the handful we have now in the UK.

I have a thoroughly worn part to copy from

In most cases this is not a problem. Most parts are worn to some extent. A 3D CAD model of the old part can be re-created. Then, by measuring the interconnecting parts, the 3D CAD model can be changed to assure a perfect fit.

I am able to borough a part for copying

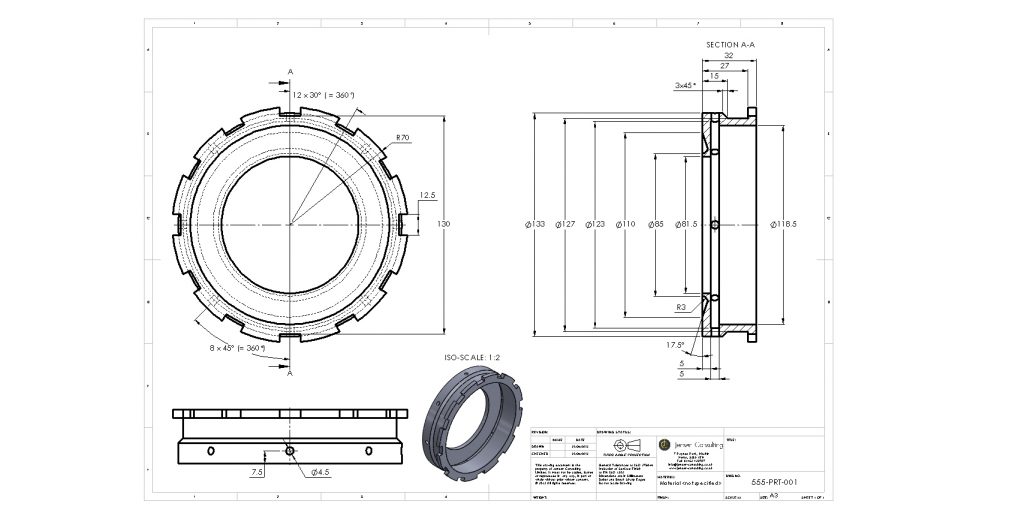

Creating a new technical drawing of an existing part can be carried out in several ways. The method of obtaining the dimensions depends on:

- Complexity

- Manufacturing method

- Required accuracy

For example a water pump housing is often cast. Therefore measuring the radii by hand can be inertly difficult. However, using a 3D Laser Scanner is a cost effective way for capturing the geometry.

Hand measuring should not be discounted due to the availability of modern technology. In most cases, measuring with Micrometres, Callipers and protractors is sufficient to replicate the part. Hand measuring should be used where high accuracy is not required or impacts on the functionality.

A combination of 3D Laser scanning and hand measuring is often good option. The 3D Laser Scan can be used to evaluate the new 3D CAD Model .

Coordinate Measuring Machines (CMM) are used where accuracy is vital. The accuracy of these machines is the microns region.

What about the tolerance?

I would like to point out that even though one can measure in microns and now re-produce in a microns tolerance the machines used to manufacture the original parts very different.

The general tolerance of the machines (CNC, Mill etc.) was much greater as today’s machines. Further, the repeatability was down to the competence of the individual.

Therefore it is always important to ask “How accurate does it have to be?” Many of us have probably made the experience that modern tolerance just does not always work on old cars and can cause new problems.

Advantages of having a drawing for a car part

There are several advantages for having a technical drawing created:

- Provide several machine shops with the same drawing to establish the best price

- You can modify the drawing to enhance the design if required

- Constantly have the same part made again and again enabling repeated quality

- CAD Drawings are provided in digital format and can be printed and shared without diminishing quality

- Get a part made on order

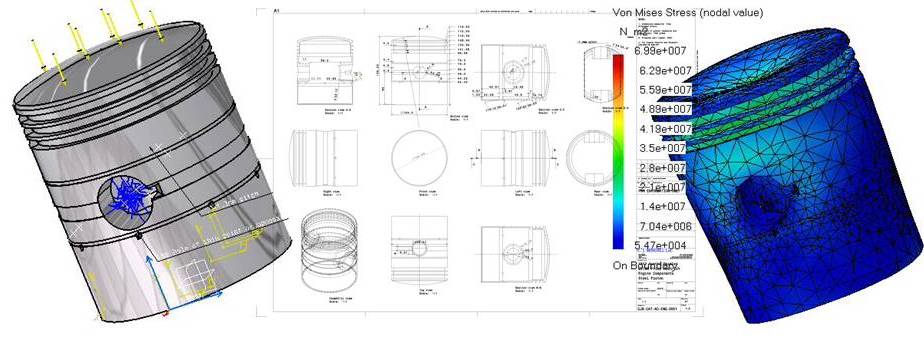

Enhancing an existing part

Enhancing parts for weight reduction, strength etc. is possible when reverse engineering a car component. Should it be done? This is an ethical question, which I believe every owner has to decide for himself.

However, modern materials, gained experience and technological advances in simulation allow existing parts to be improved.

Once a new 3D CAD model has been created any subsequent changes are simple and fast. The effects for example stresses or weight can be analysed.

Advantage of using 3D CAD

There are numerous advantages of creating the car part in a 3D CAD package.

- Changes to the model are much faster compared to 2D. The 2D drawing updated automatically.

- A 3D CAD Package allows for tolerance checking, interference checking etc.

- 3D models can be sent directly to CNC machines. This guaranties very high repeatability.

- 3D can also be used as an aid to visualise the finished component.

The process of getting a new technical drawing done

A Reverse Engineering Service will measure the part provided by methods best suited. From these measurements they will create a new 3D CAD model in a Software package such. From the 3D CAD model a 2D Technical Drawing (Blueprint) is generated. Any changes to the drawing are carried out in the 3D CAD model. The 2D manufacturing drawing is automatically updated. The 2D drawing is then issued in a common format such as PDF and or DXF/DWG.

Who can get a new technical CAD drawing made?

Anyone can get a new drawing for a veteran, vintage or classic car made. An individual might be interested as he/she does not want to be reliant on a machine shop for cost and quality. A machine shop is unlikely to issue a drawing of the part they have created. This means one is tied to the same manufacturer to guaranty repeatability. Further, not every fabricator will copy parts but all work from drawings. Also, the drawing can be kept on file and issued every time a new part is required.

Veteran, vintage and classic car restorers have requirement for a vast diversity of parts. Holding these in stock is very inefficient. With a CAD drawing these parts can be made to order.

Reverse engineering offers many possibilities and benefits and has proved to save time and money when used as part of the product development process. Restoric Design offers reverse engineering services and has 3D scanning and measuring facilities available.

Restoric Design is a UK based company operating in Hitchin and Cambridge, they provide Engineering Design Services in Mechanical Design and Product Design. If you would like to find out more about the company and the services they offer please visit their website at www.jensen-consulting.co.uk also keep up to date with them via Twitter @InfoRestoric