Rapid Prototyping aka 3D Printing

These layer building processes can be used to prototype one-offs or to direct manufacture low volume production runs from 3D CAD data. There is no tooling involved, which does not only helps to reduce costs, but also has many advantages for designers.

Costs

|

Typical Applications

|

Suitability

|

Quality

|

Related Processes

|

Speed

|

INTRODUCTION

Rapid prototyping is used to construct simple and complex geometries by fusing together very fine layers of powder or liquid. The process starts with a 3D CAD model sliced into cross-sections. Each cross-section is mapped onto the surface of the rapid prototyping material by a laser, which fuses or cures the particles together. Many materials such as polymers, ceramics, wax, metals and even paper can be formed in this way. This description will concentrate on 3 main processes: stereolithography (SLA), selective laser sintering (SLS) and direct metal laser sintering (DMLS). SLA is the most widely used rapid prototyping technique and produces the finest surface finish and dimensional accuracy. These processes are utilised mainly for design development and prototyping in order to reduce the time it takes to get a product to market. However, they can also be used to direct manufacture products that have to be precisely reproduced with very accurate tolerances.

TYPICAL APPLICATIONS

The high tolerances of the SLA process mean that it is ideal for producing fit-form prototypes that are used to test products before committing to the chosen method of production. The SLS technique is often selected to produce functional prototypes and test models because the materials have similar physical characteristics to injection moulded parts. DMLS is suitable for injection and blow moulding tooling, wax injection and press tools. This process is typically used to produce functional metal prototypes and low volume production runs of parts for the automotive, Fi, jewellery, medical and nuclear industries.

Direct metal laser sintering is suitable for making nickel-bronze electric seat adjustment cogs for use in the automotive industry.

RELATED PROCESSES

Conventional CNC machining Operations remove material, whereas rapid prototyping builds only what is necessary. Machining produces very accurate parts, but is a slow, energy intensive process. Rapid prototyping can produce complex internal shapes by undercutting, which would be time consuming and expensive to machine. Electrical discharge machining is another reductive process. Material is removed by sparks that are generated between the tool and work piece. This process is mainly used to form concave profiles that would be impractical to CNC machine. Investment casting has many of the geometry advantages of rapid prototyping because the ceramic moulds are expendable.’

QUALITY

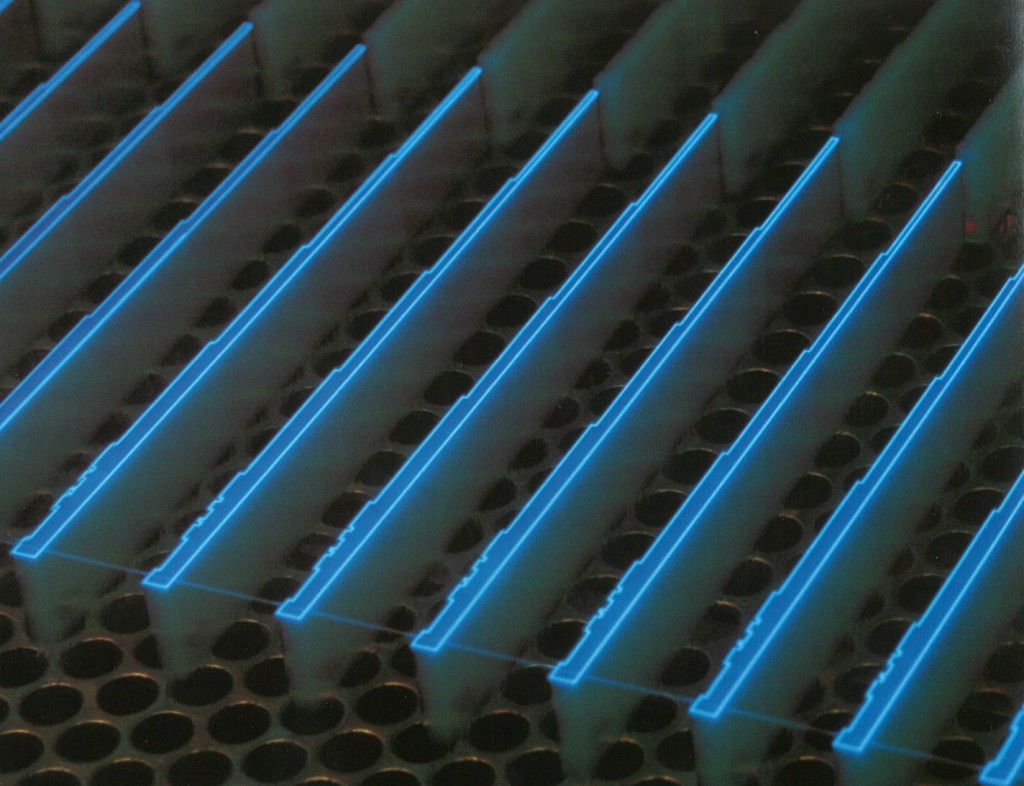

SLA techniques produce the highest surface finish and dimensional accuracy of all rapid prototyping ones. All these layer-building processes work to fine tolerances: SLS builds in 0.1 mm (0.004 in.) layers and is accurate to ±0.15mm (o.oo6 in.); SLA forms in o.o5—o.1 mm (0.002—0.004 in.) layers and is accurate to ±oi mm (0.006 in.); and DMLS builds in 0.02—0.06 mm (0.008—00024m.) layers and is accurate to ±0.05 mm (0.002 in.). Above left Direct metal laser sintering is suitable for making nickel—bronze

As a result of manufacturing 3D forms in layers, contours are visible on the surface of acute angles. All of the parts therefore require finishing when they come out of the machine. It is possible to acquire a very high ‘glass-like’ surface finish on the water clear SLA epoxy resin, by polishing. Micro modelling can be used to produce intricate and precise parts (up to 77 x 6i x 230 mm/3.03 x 2.40 x g.o in.). This process builds in 25 micron (0.00098 in.) layers, which are almost invisible to the naked eye and so eliminates surface finishing operations. These Layer building processes can be used to prototype one-offs or to direct manufacture Low volume production runs from CAD data. There is no too Ling involved, which not only helps to reduce cost, but also has many advantages for the designer.