Can one Laser Scan and output directly to CNC machine

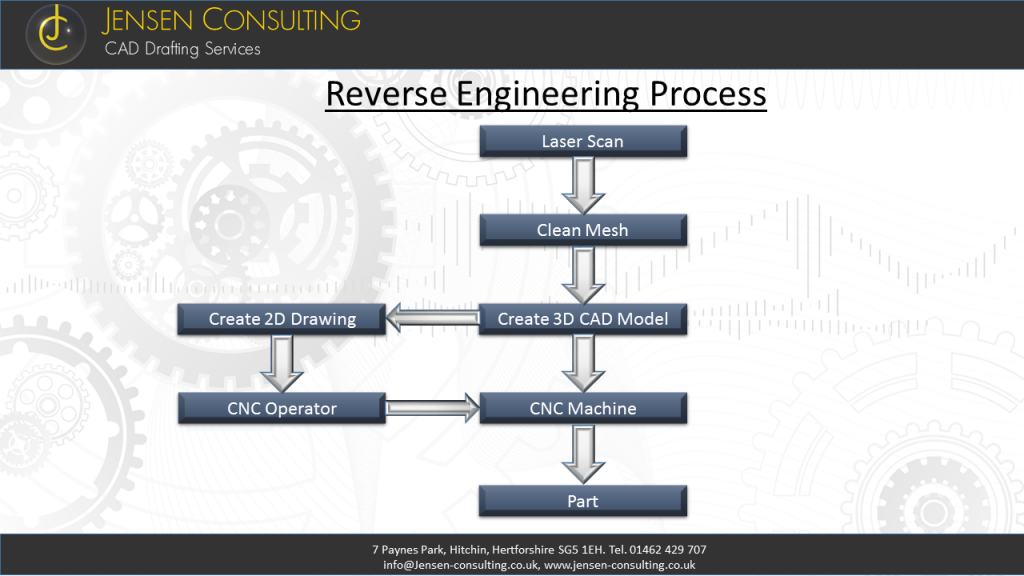

Reverse Engineering Process

As a Reverse Engineering Company we often get asked if we can Laser Scan a component and “just” output it to a CNC Machine. I believe this is due to the some low cost Laser Scanners on the market trying to slightly oversell their capabilities.

The actual process is not that simple.

Step 1 – Laser Scan Part

There are many 3D Laser Scanners on the market with a price range of <£1,000 (such as the Sense from 3D Systems) to +£20,000 (such as Romer Scanner) The cheaper options are not really the right application for measuring/scanning mechanical components.

Step 2 – Clean Mesh

The Laser Scanner produces a mesh cloud. This mesh will include any imperfections of the part and potentially some areas where the mesh was not produced accuracy (which can have a number of reasons such as reflectivity etc.) Further, there might be multible scans required that need to be “stitched together”.

Step 3a – 3D CAD Model

Based on a clean mesh a new Solid CAD model can be produced. A 3D CAD Service will use Software packages such as Solidworks to produce a accurate 3D Solid Model based on the mesh data. This CAD Model can then be exported in different formats for example Step or Iges.

Step 3b – 2D Drawings

It is also a common thought that 2D Drawings are no longer required, as the 3D Model can be directly input to the CNC machine. This is not correct for most applications.

A Manufacturing Drawing is required as it will show information for the CNC Operator like:

- Material

- Surface Finish

- Linear & Angular Tolerances

- Hole Specifications/Thread Types

- Geometric Tolerances

Step 4a & 4b – CNC Operator & machine.

The CNC Operator will input the 3D CAD file into the CNC machine. He will also use the information on the 2D Drawings to select tooling/speed etc.

Based on this information the CNC machine will be able to produce the part.

Conclusion – Can one output a Laser Scan directly to a CNC Machine

No one can not.

There is a process involved that requires the knowledge and capabilities of a Reverse Engineering Company.

Please contact Restoric Design on 01462 429 707 or info@jensen-consulting.co.uk for more information on their Reverse Engineering Services.