Technology has been a blessing to the engineering industry. However, some people are still resistant to the idea of computer-aided design (CAD). Here, we’re going to take a look at the major benefits of using technology to plan your next project.

It allows you to draw to scale, and to change this easily

Needless to say, the more accurate and to-scale your design, the better. Now, if you’re doing your planning manually – and all due respect if you are – you’ll need to work out your scale before you start the actual work and then stick to it.

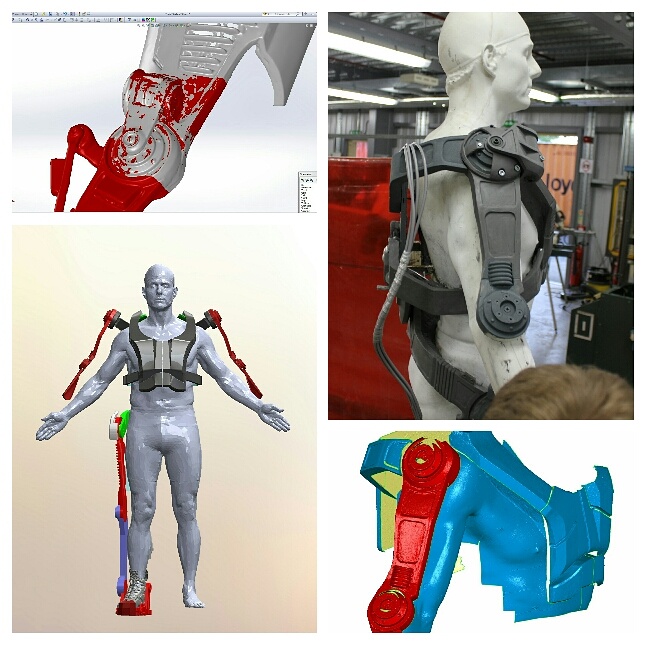

CAD gives you an element of flexibility that you simply don’t have when going manual: you can produce your designs in either 3D or 2D, have free reign to rotate or alter them, and you can change the scale with relative ease.

It can help you become more productive

In the end, time is money to any business, and CAD can help you save a lot of time! Put simply, CAD minimises mistakes. When doing things manually, even a skilled engineer can’t be totally sure his plan will work until it’s put into action. This can lead to mistakes having to be rectified, and in engineering, rectifying mistakes can use up man hours fast.

With CAD, you’re able to test a number of things during the planning process. This means you can see immediately if any modifications are needed and can make them.

Put simply, CAD helps you to minimise errors that can be costly to fix.

It’s easy to make edits

You can always change things to make your product more efficient. However, it’s a lot easier to do this when changes are quick to make, which is the case with CAD.

If you’re doing things manually, however, making even smaller changes can be a very time-consuming process. Indeed, some less pro engineers might be tempted to not even make changes if the product will function OK without them.

As a result, CAD takes away one of the major obstacles to a better, more efficient design.

It’s more accurate

This seems like a harsh judgement, but unfortunately, it’s the truth: even the most skilled engineer can’t mimic the accuracy that design software is capable of.

Every single measurement in the design can be adjusted right down to the smallest levels, giving you total control of everything. Again, this means a higher quality of work in far less time.

You can easily duplicate

If there are certain features of a design that can be re-used for other parts of the project, CAD will allow the engineer to do this quickly and with the minimum of effort.

In the days of manual design, engineers simply had to repeat their process over and over again, even if the details of certain areas were the same. Needless to say, making manual copies of anything is a substantial time suck. A time suck that CAD has thankfully saved us from!

You can easily share everything

Big projects mean big teams, and big teams mean a lot of information flying all over the place. CAD software allows for easy, quick file sharing. If one member of the team wants to have a look at a particular set of plans, they just need to log on and find the relevant folders.

Even if you have thousands of blueprints in place for a particular project, CAD software makes finding the right one a matter of seconds. In the manual days, going through filing cabinets one by one was the only option!

Find out more

If you’re interested in finding out more about how CAD could benefit your next project, give us a call today. We’ll be happy to help.