To create realistic and accurate models of surfaces and objects 3D Modelling is ideal. It utilises software like AutoCAD. And specialist software tools like Advance Steel, and a skilled 3D modeller can create digital replicas of existing items. Another, popular use for 3D modelling is in the design and even the printing of prototype models. Prototyping allows all stakeholders to more easily visualise a product. The process can also be used to reduce development costs. It can be used to identify and implement changes and improvements.

Proof of concept

A 3D model, based on early designs, can be used to create a proof of concept. A digital proof of concept can be beneficial, but a physical proof of concept enables designers and engineers to identify potential changes early in the design and manufacturing process. This means that the designer will be able to identify problems early on, but it also enables clients to identify material requirements and use the proof of concept to authorise resources.

A proof of concept 3D model, developed early in the process, can help to expedite the process of manufacturing and producing products before they go to market.

If funding is required for a project, a proof of concept is critical. Potential investors may be willing to invest in an idea, but if you do not have a visible track record of successfully designing and profiting from the launch of new products, then you will need a physical product to show off. Prototyping means that you can provide this proof of concept without having to invest heavily before receiving funding.

Required changes can be identified

Additive manufacturing, or 3D printing, means that it is feasible to create prototypes at regular intervals. The costs are lower than manufacturing a prototype, and the prototype model can be used to identify changes. Whether these changes are structural, aesthetic, or technical, using a prototype model means that changes can be identified and a new model produced. Regularly updated models allow us to show proof of concept to the client, and involve them in the process too.

Meet specific design requirements

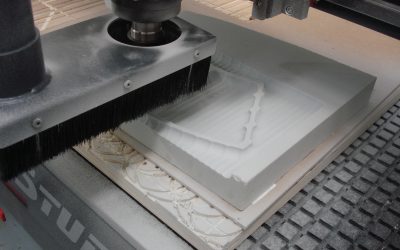

A major obstacle to manufacturing prototype’s is it can be extremely cost prohibitive to manufacture a single concept product. This means that it is rare for prototypes to be printed early in the process, when using traditional manufacturing processes. Using digital prototyping or, better still, printing a 3D recreation of the product, can be undertaken at lower cost and with greater speed and convenience. It is possible to create totally bespoke designs, and the intricacy of 3D modelling means that it is possible to print individual components, so that they can be individually checked, and improvements and changes can be identified.

3D printing offers cheaper prototyping methods

3D modelling is ideal for prototyping. Quick and easy access to a working model. Whether it is virtual or physical. This means that engineers, designers, and other stakeholders including clients, can get involved in the design process. It is cheaper than using traditional manufacturing methods. It will lead to less waste and fewer errors than using traditional manufacturing or waiting until the end of the process before visualising a product. This reduces the time that it takes to complete the process of designing products. Also producing them, and meeting quality control requirements.

Prototyping and 3D modelling are important elements in the manufacturing and design process. They help to cut costs and reduce waste, minimise errors, and improve the overall process involved in manufacturing new products. Create proof of concept models, use 3D modelling to assist in 3D printing, and identify any improvements that can be made during the early stages of the design process.