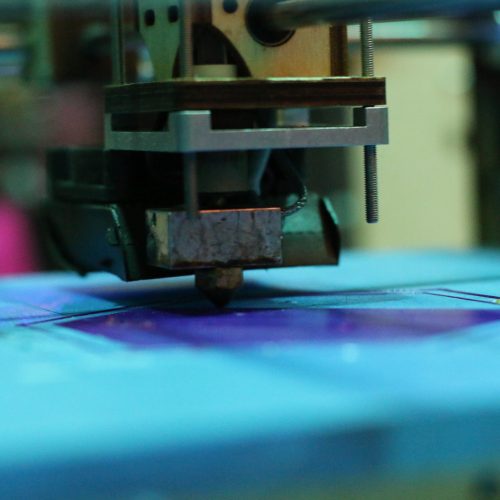

3D printing has enjoyed some impressive advances in the past few years. From new materials to faster printing times, it’s clear the technology is here to stay. The product sector has been revolutionised by 3D printing, and its time for architecture to follow their lead.

Help others recognise your design

People who sign off on funding are not always technically inclined. It can be difficult to convey your vision with pictures and videos. Realistic renders are a great way to show a sense of scale, but 3D prints will show the true magnitude of your project. As investors get a better idea of the project you are proposing, you can go in depth without losing their attention. There is no need to fiddle with files and go back and forth between floor plans and renders. A real-life, exact model of the building will capture the attention of your investors.

Traditional model vs 3D model

True, you could just have a scale model built in the usual way. A couple years ago and it would have made sense. But in 2018, the industry has come a long way. A 3D printer is still a costly venture, but you can easily outsource your model to a multitude of eager companies. A model can be quickly printed in a few hours, saving you precious building time. The print will be stronger and resistant to rough handling and water damage. All-in-all, a better choice for your model needs.

Reusability

A 3D model can be changed, moved apart and joined to other sections. You can build a library of basic modules to build a whole design or help rethink the boundaries for a design. If your project requires a large number of duplicate components, 3D printing can speed up the process. Quickly print a cast and use injection-mould techniques to recreate exact replicas at high speed.

Unlimited designs

Using software like Steelworks, you can build a custom design and print it out as a Rapid Prototype. You can test out designs in a real-world format with lighting fast speed and accuracy. If there is a structural issue, identifying it and fixing it is a simple task. You can print scale designs that would be too timely or intricate for traditional modelling techniques to handle. Precise curves and complex shapes are not the time suckers they used to be. With no limits on your to-scale model, you can design a true masterpiece.

Cost

3D printing has been avoided for years because of the high costs involved. A medium sized printer can easily set you back £1100 and a large one over £2000. That is before you’ve even considered the running costs and maintenance. The more cost-effective (and simpler) way is to outsource your printing. By sending your printing to a professional, you ensure good quality prints without worrying about the details. Many architectural firms are choosing this route to give their designs an extra twist

Is 3D printing the way forward

While photorealistic renders will always have their place, 3D printing is leading the way into the future. The versatility it offers is unbelievable. You can even choose your printing material – wood, concrete and resin being only a few options. Never before has it been so easy and quick to create high-quality scale models. With speed comes better profit margins and happy managers, improving the architectural industry as a whole. There is no need to waste time building models by hand. Instead, outsource your model needs and spend time on what really matters – the design.