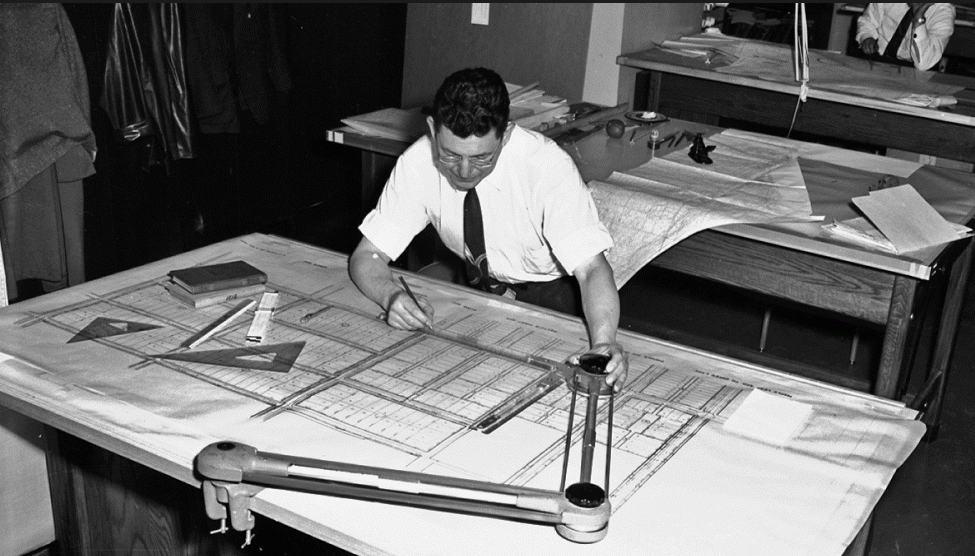

The early days of space travel still relied heavily on pen and paper, numerous pots of strong coffee, and a room full of mathematical geniuses working around the clock to design the latest prototype. Even with all the expertise and intellect in the world, flaws and faults still fell through the cracks sometimes with deadly results.

It’s perhaps slightly strange that we, as a species, managed to travel a quarter-million miles to the lunar surface before we managed to make computers an everyday and easy to use appliance. But now times have changed – famously, the Apollo XI Lunar landing module had less processing power than even the most basic smartphone you can buy nowadays.

CAD has its roots in rudimentary programmes in the late 1950s, but it would take several decades of development and finessing before computers could be used to design space vehicles. But the advent of more sophisticated and versatile CAD software packages being released in the 1980s, such as AutoDesk AutoCAD, signaled a change. The Space Shuttle Enterprise, the world’s first reusable spacecraft, was partially designed using industrial CAD programmes. Since then, the technology has become absolutely integral in our ventures to the stars.

But what exactly makes CAD software so useful to scientists and designers?

Well, with such intensely complex systems and components to plan and produce, using software instead of a straight-edge and a Bic means that project timeframes can be absolutely slashed. Equally, the aerospace and space industry are both famous for championing and developing new high-tech materials such as Kevlar and carbon-fiber. CAD software can replicate the material qualities – torsional strength, heat retention, and weight – without the need for manual calculations.

One of CAD’s most advantageous traits is the ability to predict danger before it ever happens. Breaking out of the stratosphere has not been easy nor free of casualties, and the extreme conditions beyond Earth mean that any mistake or design flaw could be deadly. Sophisticated packages such as Solidworks, Steelworks, or AutoCAD, can simulate conditions – how a building copes with high winds, how a car’s suspension reacts to a cobbled street etc. – and this massively reduces risk. With CAD, a flawed or unsafe design will never be allowed to fall through the safety net.

With manned missions to Mars on the horizon, what role will computer-aided design play in humanity stepping foot on another planet?

Much like any new car or plane, every component of contemporary space-vehicles such as SpaceX’s Falcon rocket or NASA’s Curiosity Mars rovers, have all been meticulously designed with the help of computers. Cost, development time, and danger – these are all factors that could cripple any vehicle design, and these are all things that CAD helps to reduce.

Away from the formulae and mechanics, CAD may have another part to play in this story and that is in the cockpit. Luxury space travel has been a talking point in the last few years, and someday it may come to fruition. If this should happen, we may very well see spacecraft interiors designed to be comfortable for travelers. This is a long way off, for sure, but only around 100 years separate the Kitty Hawk and an Airbus A380, so it is not impossible.

Of course, space travel is a highly specialised application of CAD and the likelihood that you, the reader, are in need of a 3D model for a Saturn V class rocket for a quick trip to the Moon is rather low. But we can help you with a whole host of 2D and 3D modelling and rendering with our CAD services.

If you are looking for CAD outsourcing for quality rendering, schematics, or modelling then contact our talented team of designers today to discuss your project – we may even be able to design your dream luxury spaceship.