Steel detailing is an incredible art that ensures structures are made to the highest standards possible. For a structure to achieve high standards, it is essential it goes through a steel detailing process which requires total accuracy. Engineers and architects may be experienced in drawing and creating plans for a structure, but without the proper technology, even they are not qualified to achieve the high levels of fabrication needed. Detailing requires extreme precision as even the smallest of errors can be harmful to a structure and lead to the loss of both time and money.

How CAD makes it possible

The original code for computer-aided design (CAD) can be traced to the year 1957, but it did not become accessible to engineers till the late 1970s. After it became available, engineers and architects came up with modifications to suit their needs which finally led to advancements in steel detailing hence eliminating the need for manual drafting. Since then, the technology sector has advanced so that we can make it more safe, efficient and comfortable to build buildings as a result of improvements in steel detailing.

Why is CAD being used?

One of the most significant reasons that CAD is preferred in detailing is because of the increased accuracy that it can bring. Though papers and pens were the tools used in the past, their inaccuracy often led to errors in work.

The vector images that are used in CAD are mathematically right. That means that the system makes no error while detailing and human error is eliminated since the software is always backing up the design. Here are some of the benefits of using CAD in steel detailing…

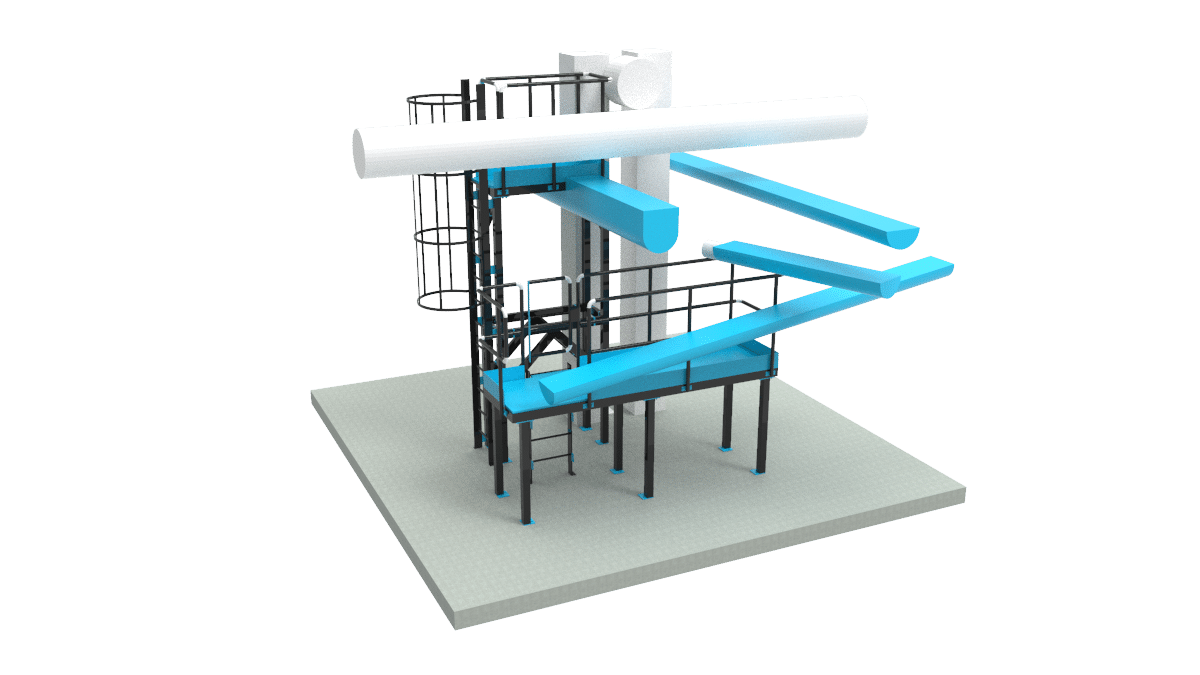

1. CAD can create 3D models in steel detailing

If you are a steel detailer and have tried creating a 3D model manually, you can admit that it is incredibly cumbersome and time-consuming. The traditional 2D design also means that steel detailing can often be misinterpreted, creating further problems.

2. Better precision

Making use of CAD software can help increase the accuracy of a drawing. Steel detailing needs detailed drawings that are used by contractors, architects, and engineers. In such projects, where every small detail matters, CAD is very beneficial. As the margin of error is reduced, better results and better structures can be created.

3. CAD can be modified quickly

Modifying a product that you had previously designed is much easier with CAD as you are able to make a second generation of the same product with ease. What makes it more exciting and worthwhile is that you can successfully save a model or product in a file for ease in tracking. You can also alter the product to fit the customers’ needs, preventing the hassle of restarting a project from scratch.

4. It is easy to learn and use CAD

It is a common misconception that CAD software is difficult to use. If you have been able to work with manual drafting, especially in steel detailing, you can be sure that learning CAD will be not only achievable but enjoyable. If you work with steel detailing, you will already be used to thinking spatially, hence making you an excellent candidate to use CAD. The best part of learning CAD is that it uses simple tools that you will already interact with on a daily basis, such as copy, paste, and cut, which help you feel more familiar and confident when learning CAD.