Despite steel detailing being a critical part of many constructions and design projects, there is very little awareness outside of the industry of what the job actually entails. Needless to say, knowledge about what steel detailing is, how it’s done, and why it’s essential on every job site, should be more common. That’s why, here at Restoric Design, we’ve comprised a list of the most common questions surrounding steel detailing and answered them so that more of the general public know about this wonderful job and its benefits.

What is Steel Detailing?

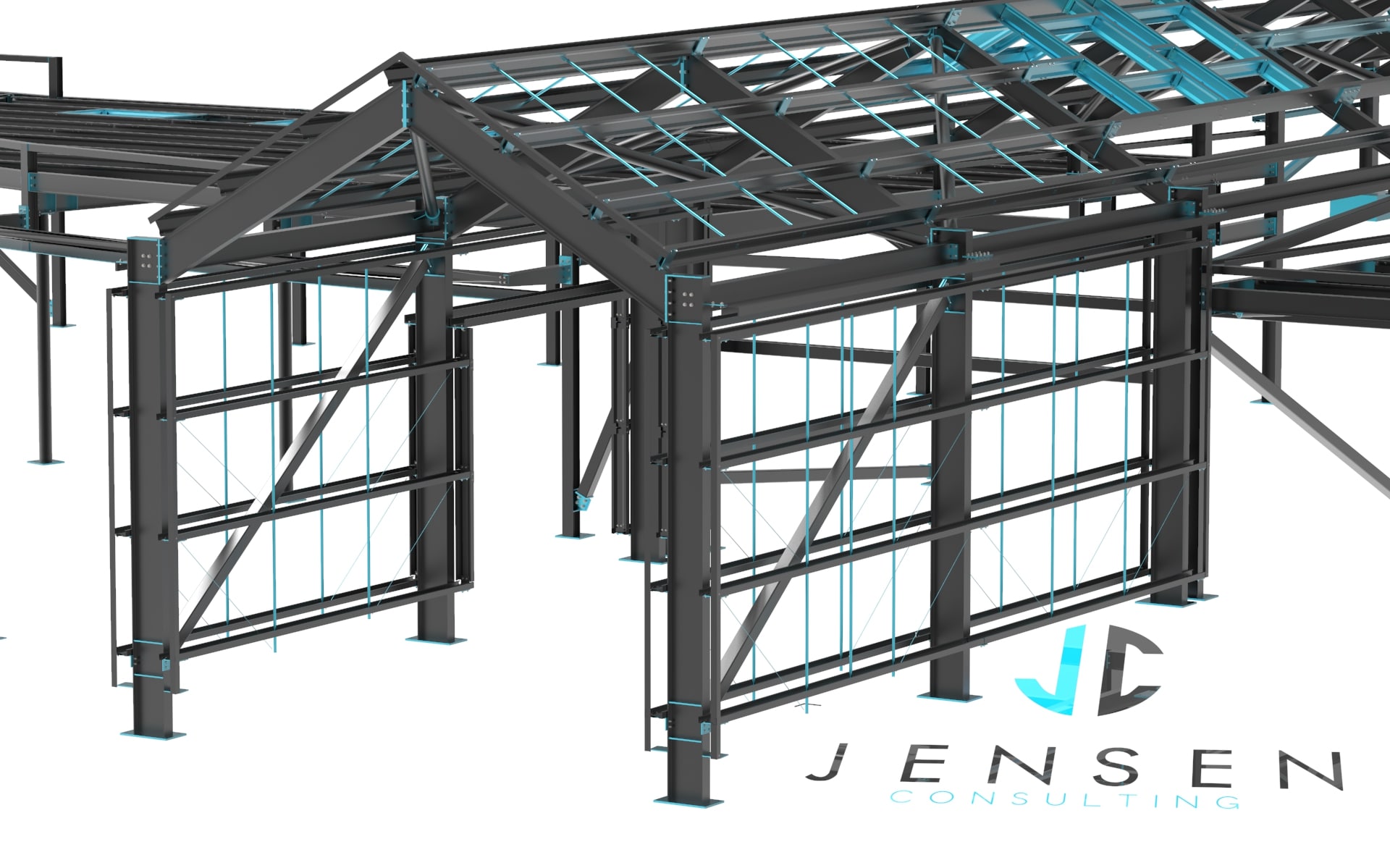

Steel detailing is a profession wherein detailed drawings, plans, and documents relating to the manufacturing of steel members are produced. These plans are passed on to steel erectors and fabricators so that the steel members required for any construction project can safely and accurately be designed, created, and assembled.

The steel members in question can refer to a wide variety of parts, such as anything from columns, braces, beams, and joists, to trusses, handrails, staircases, and metal decking. As such, some steel detailers specialise in one type of design, while others are generalised and can work with a variety of briefs.

Steel detailers are just one step in a long process of construction and design. Because of this, their work is rarely isolated; rather, people in the steel detailing profession tend to work closely with architects, steel fabricators, general contractors, and engineers.

How is Steel detailing carried out?

Though traditional steel detailing was carried out manually with a pen, paper, and drafting tools such as a parallel bar, times have now changed and adapted to suit the modernised digital world. Now, the majority of steel detailing is done using computer-aided design (CAD), of which detailers can use specialist software to detail the steel plans. These plans are then printed out in physical copy only when the design is complete in order to minimise paper waste.

Some of the skills required to be a steel detailer include drafting, communication, spatial realisation, logic and reasoning, and mathematics. Not only this but an – at a minimum – basic understanding of engineering and physics will complement the process of steel detailing greatly. Weakness in any of these areas could result in poorly designed steel draughting, which in turn could waste material, time, and employee labour – as well as being potentially fatal.

Why is Steel detailing an important part of the design and construction process?

Steel detailing ensures that the construction of any steel components of a project is safe, concise, and abide by all necessary regulations. Without steel detailing plans being drawn up, engineers and general contractors could run the risk of their project taking more time or wasting more resource than necessary.

Steel detailing is also one of the very important roles that link other professions together during a project. Without steel detailing plans in place, accuracy is likely to be lower and the risk of injury rises. So overall, it’s clear that steel detailing is an intrinsic component in the design and construction process. Don’t risk your project by skimping out on hiring a professional – you’ll only fall foul later and possibly have a hefty price to pay.

If you’re running a construction project, make sure you have a professional steel drafter hired. Here at Restoric Design, we have a great team of expert steel detailers just ready and waiting to help. Browse our website today to see the full list of steel detailing services offered, as well as getting in touch via the contact page, email, or over the phone. We’re happy to answer any queries you may have!