Steel detailing is a drafting process which assists the fabrication of hot and cold rolled steel. It involves creating detailed drawings for contractors and fabricators. This process is essential as it provides an important link between professionals such as architects, engineers, fabricators and contractors. Steel detailing is used in the construction of bridges, buildings, nonbuilding structures and industrial plans. To learn more about the process of steel detailing, continue reading.

Early stages

Steel detailing is a multi-layered process in the construction sector. Firstly, the structural engineer or architect will put forward an idea about a project, and give a general description on paper. The drawing they produce could be linked to mechanical systems which relate to steel members and their fabrication. The steel detailer will take these early drawings and transform them into detailed and accurate diagrams for each steel piece. These plans and drawings could refer to the making of steel members such as trusses, beams, braces, columns and joists.

Shop drawings

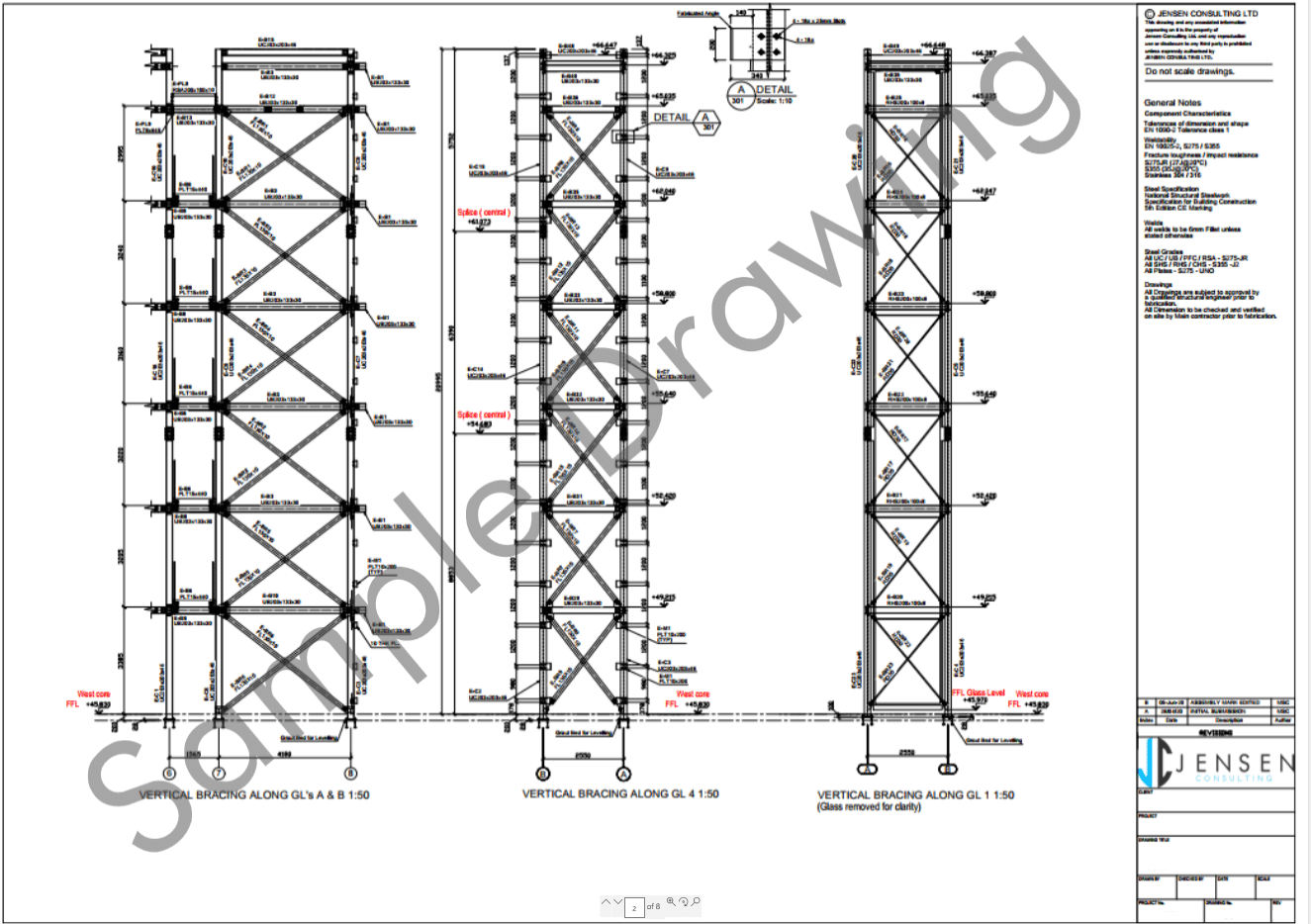

These meticulous drawings produced by the steel detailers are known as shop drawings. They denote the exact specification for fabricating each member of a structure. Comprehensive shop drawings include many elements. Among these include size, required dimensions, material description, preparing surfaces, welding, painting and manufacturing conventions.

Erection drawings

The steel fabricator produces structural steel members based on the detailer’s shop drawings. Next, the steel detailer will step in again to produce erection drawings for the steel members in the field. These drawings will be referred to by the steel erector so that they know where to build with the steel pieces. Within the erection drawings, the detailer will include dimensional plans. This is to identify the steel members in addition to all the other work needed on the site, including bolting, welding and installing masonry anchors.

Techniques used

Steel detailing has utilised new technology to produce high-quality designs. Previously, steel detailing was carried out on paper, using pencils, rulers and triangles. In today’s world, steel detailers use Computer Aided Design (CAD). This is a software which allows designing in 2D. It has revolutionised the industry, making things faster and easier while also more cost-effective. Most companies now use 3D CAD. This model has an additional z-axis, which allows diagrams to be created in 3D. With this computer software, projects can easily be scheduled and tracked. This creates a high degree of output with very high accuracy.

Additional tasks

As well as completing the above tasks, the steel detailer may also have some other responsibilities. They may have to present drawings to the structural engineer before they are released to the fabricator, to be evaluated. They also have to observe parameters of design drawing and make sure they comply with industry standards. To check the accuracy of their design, the steel detailer may send their drawing to another steel detailer. If there are cases where there is insufficient information about structural drawings, they may offer links subject to the structural engineer’s sanction. Finally, it is essential that they resolve any comments or issues that may have come out of the approval process.

Restoric Design can provide steel detailing for your business. With our focus on consistent quality, regular communication and timely delivery, we can find the right solution for you. For more information, contact Restoric Design today.