Steel detailing is a vital aspect of engineering projects that require pinpoint precision in terms of planning, designing and implementing steel components. Shop drawings are created using steel detailing, which can then be used to assemble and install all steel elements including beams, platforms and more.

Employing steel detailing in projects demands precise work that was originally done by pencil and paper alone, but today is powered by digital innovations. We’re going to take a look at how steel detailing benefits projects, from cohesive collaboration to streamlining project processes.

How is steel detailing used?

Traditionally, steel detailing was implemented using simple, meticulous methods that used pen, paper and protractors to create precise steel designs. Today, technology has driven a more effective approach to steel detailing using innovative software and hardware.

Nesting software is used to digitally fit various steel components into a sheet of steel. Using flattened, 2D patterns of components that will be cut from sheets of steel, nesting software can create the most efficient cutting paths to make design faster and minimise waste.

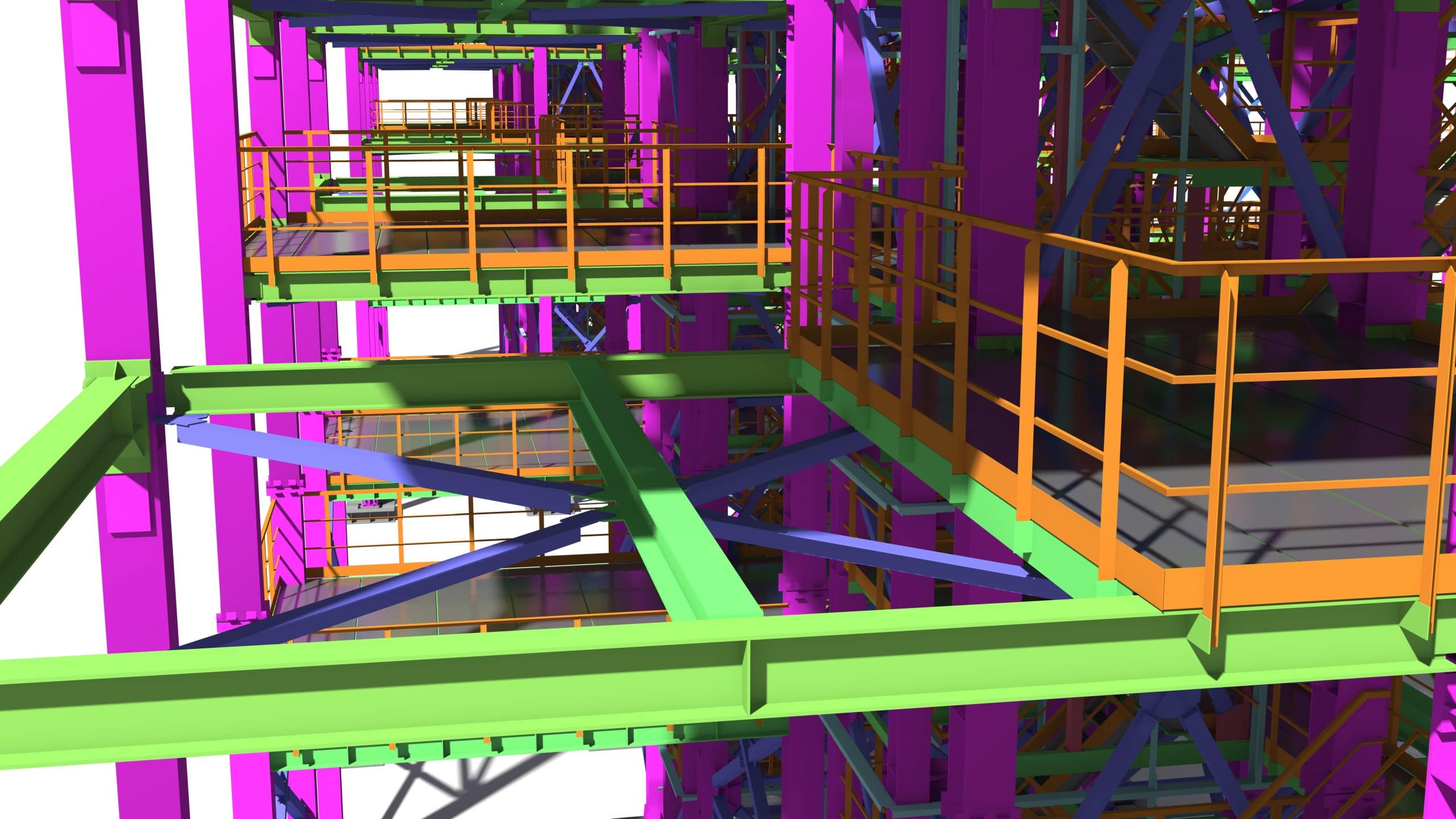

3D BIM modelling software, such as Advance Steel, uses 3D models to layout the design of projects on a large scale. Designers can use the 3D models to create 2D drawings which can be used for fabrication down the line, but it also provides a lot of information such as lists of required materials and shop floor drawings.

CNC machines, also known as Computer and Numerical Controller machines, use pre-programmed coding to manufacture components automatically. This intricate process takes a lot of stress out of the construction aspect of a project, as it mitigates accidents and faulty designs.

The benefits of modern steel detailing for projects

Bringing 3D designs into projects

The problem with detailing prior to the above innovations was that it relied heavily on 2D drawings, which are inherently lacking in information. Trying to apply 2D models to 3D projects is difficult and can lead to errors, which can affect timescales and budgets. In the event that an error is not picked up and is used during construction, going back to correct even small mistakes can cost a substantial amount.

Transitioning to a 3D model through modern steel detailing is much less prone to errors and can automatically flag issues such as design flaws.

Empowering projects with useful information

Software such as BIM allows for a much richer pool of information to be shared across a project. Things like required raw materials, weld links and other useful information can all be brought into a project using BIM.

4D scheduling is another innovation that can make it easier to plan ahead and track the required components and materials for a project. This is particularly useful at the pre-planning stage, as it improves timescale accuracy and offers more realistic budgets.

3D modelling is also incredibly useful in terms of collaboration across teams and sectors of a project. 3D models provide clear, transparent instructions that make them more useful for everyone involved in the project. From tracking the progress of a team to understanding what implementations are coming next, 3D modelling makes communication easier and more constructive.

Project success thanks to modern steel detailing

Innovation is often a driving factor in a project doing well during its lifespan, with steel detailing providing a host of features that increase accuracy, productivity, communication and accountability. With important advancements in the industry such as 3D modelling and BIM, project leaders and stakeholders are much more likely to reach their project goals on time and to budget.

If you’re looking to use a steel detailing company in your next project, speak with our specialists at Restoric Design today to discuss your requirements.